In the aerospace industry, the demand for high-performance materials is constantly growing. As technology advances, the need for materials that can withstand extreme conditions such as high temperatures, high pressures, and corrosion becomes increasingly urgent. This is where metallographic analysis equipment comes into play, serving as an essential tool for aerospace material innovation.

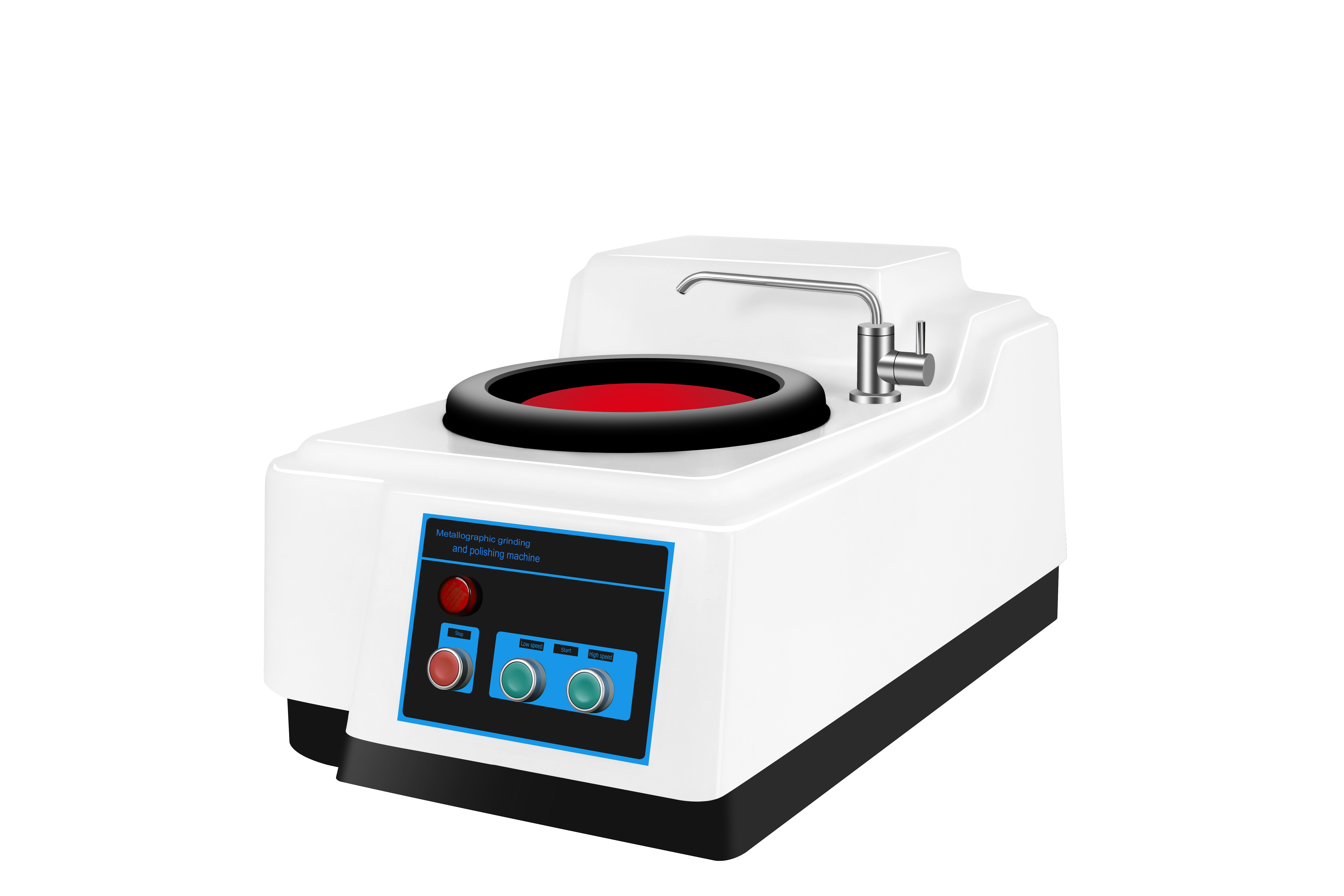

Metallographic analysis equipment operates on the principle of examining the microstructure of materials. By preparing samples and using microscopes and other tools, it can reveal the internal structure of materials at the microscopic level. This equipment has multiple functions, including identifying the phases and structures of materials, measuring grain size, and detecting defects. According to industry research, the accuracy of modern metallographic analysis equipment in grain size measurement can reach up to 0.1 microns.

One of the key characteristics of this equipment is its high precision. For example, the high-definition continuous zoom video microscope used for precise analysis can provide clear and detailed images of the material's microstructure. Another characteristic is its versatility. It can be used to analyze various types of materials, such as metals, alloys, and composites.

In the aerospace industry, metallographic analysis equipment has a wide range of applications. Take the manufacturing of aero-engine blades as an example. These blades need to operate in high-temperature and high-pressure environments, so the quality and performance of the materials are crucial. Metallographic analysis equipment can be used to examine the microstructure of the blade materials during the manufacturing process. A research report shows that by using this equipment, the defect rate of aero - engine blades can be reduced by up to 30%.

Another important application is in the research and development of new aluminum alloys. Aluminum alloys are widely used in the aerospace industry due to their low density and high strength. Metallographic analysis equipment helps researchers understand the relationship between the microstructure and properties of new aluminum alloys, enabling them to optimize the alloy composition and processing technology. For instance, a recent study found that through metallographic analysis, the strength of a new aluminum alloy could be increased by 20%.

In terms of material innovation, metallographic analysis equipment provides valuable insights into the microstructure of materials, which helps researchers develop new materials with better performance. For quality detection, it can quickly and accurately detect defects and inhomogeneities in materials, ensuring that only high - quality materials are used in aerospace products. In terms of safety assurance, by preventing the use of substandard materials, it significantly reduces the risk of aerospace accidents.

Metallographic analysis equipment plays an indispensable role in the aerospace industry. Its importance in promoting material innovation, ensuring product quality, and guaranteeing safety cannot be overstated. With the continuous development of the aerospace industry, the demand for more advanced metallographic analysis equipment will only increase. The future of metallographic analysis equipment in the aerospace field looks very promising.

Don't miss out on the opportunity to enhance your aerospace material innovation and quality control. Contact us now to learn more about our state - of - the - art metallographic analysis equipment!