Automated Transmission of Microhardness Test Data via RS232 Interface for Seamless LIMS Integration

07 01,2026

Tutorial Guide

This article focuses on the automated transmission and traceability management of microhardness test data, detailing the application of the RS232 interface in the Laizhou Jincheng Industrial Equipment HVS-1000A microhardness tester and its seamless integration with Laboratory Information Management Systems (LIMS). By implementing standardized data formats, real-time data upload, outlier processing, and multi-user access controls, the solution enhances digital testing workflows for university laboratories, research institutes, and third-party testing organizations. Practical scenarios and case studies demonstrate improvements in data reliability and collaborative efficiency, driving comprehensive informatization in scientific research and quality control.

Automating Microhardness Test Data Transfer: Leveraging RS232 in LIMS Integration

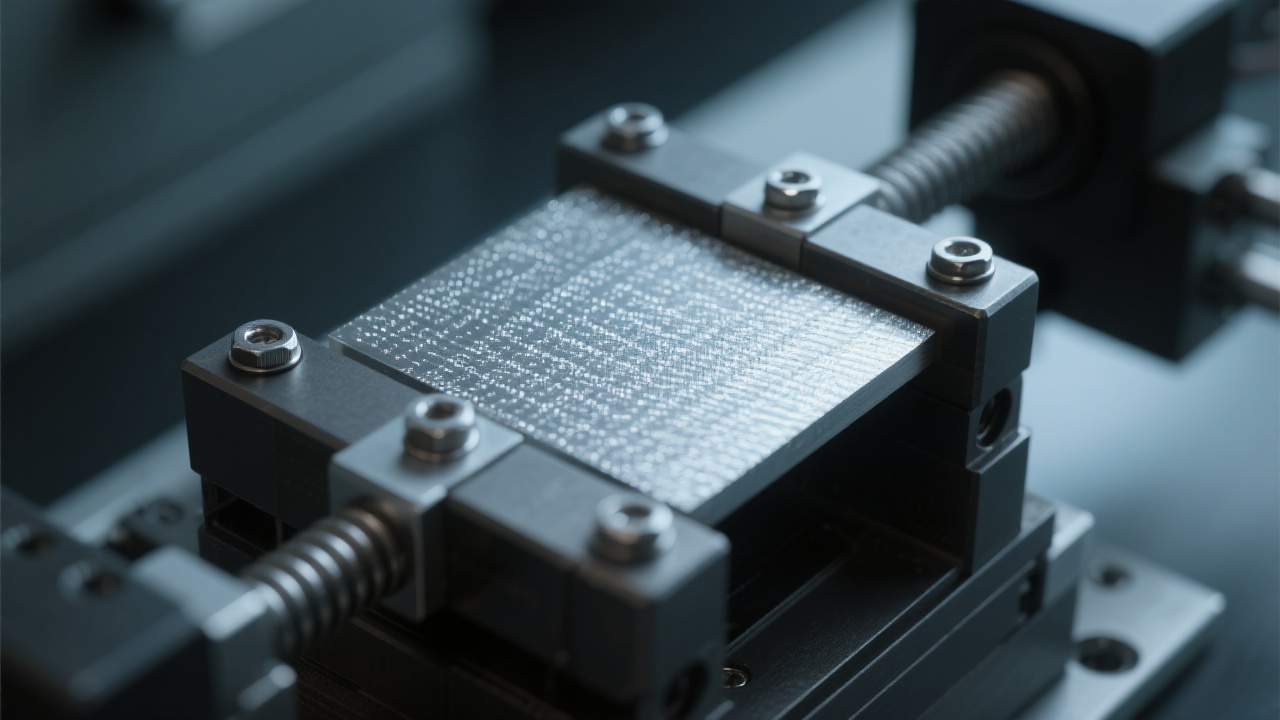

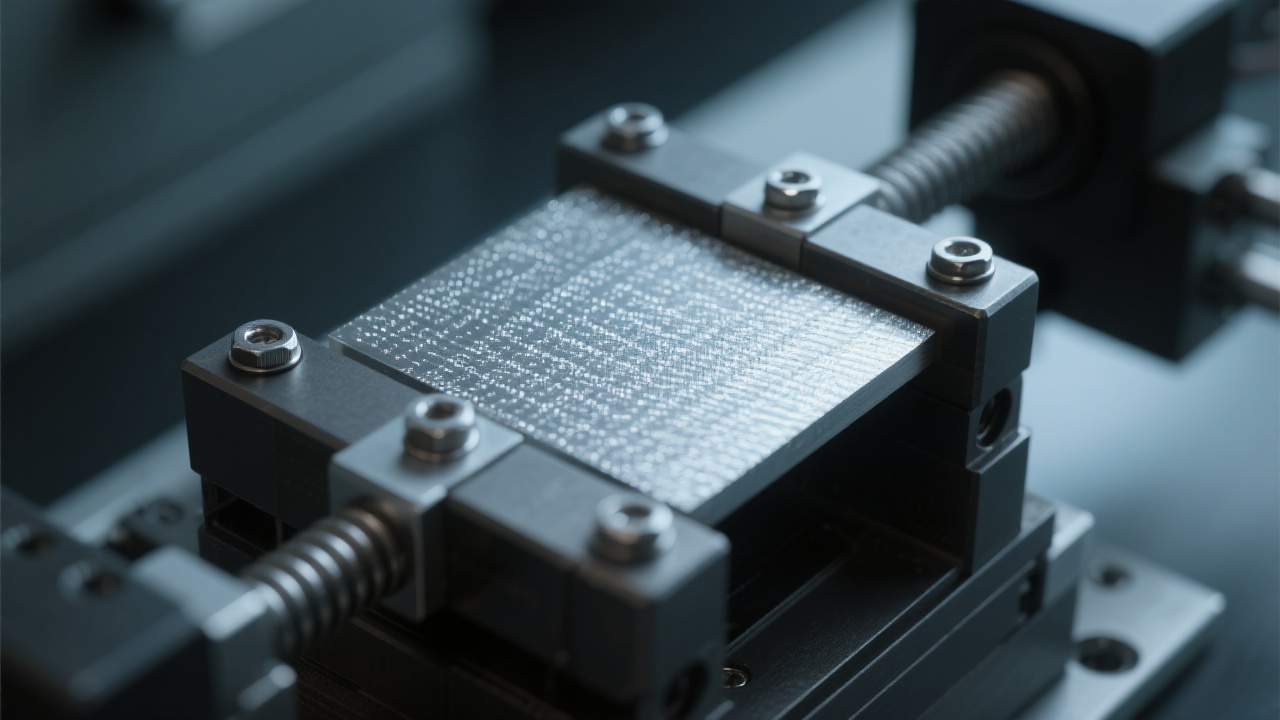

In the realm of materials science and quality control, microhardness testing serves as a pivotal technique to assess the mechanical properties of materials with precision. However, managing the voluminous data generated by microhardness testing devices can present challenges—ranging from manual entry errors to difficulties in traceability and data analysis. To address these challenges, automated data transmission systems become indispensable. This article delves into how the RS232 serial interface facilitates seamless integration of microhardness testers like the HVS-1000A by Laizhou Jincheng Industrial Equipment Co., Ltd. with Laboratory Information Management Systems (LIMS), enabling highly efficient, reliable, and traceable test data management.

The Imperative of Automated Data Transfer in Microhardness Testing

Microhardness testing is crucial in both academic research and industrial quality assurance, providing insights into material behavior under various conditions. Yet, the data generated, including indentation measurements and calculated hardness values, often suffer from time-intensive handling and risk of human errors during manual transfer. Typically, laboratories face the following data management challenges:

- Data transcription errors leading to questionable results

- Limited data traceability and version control

- Delayed availability of test results impacting decision timelines

- Inconsistent formatting complicating data analysis and reporting

The integration of automated data transfer mechanisms significantly reduces these issues by ensuring data accuracy, improving traceability, and expediting workflow.

RS232 Interface: A Reliable Backbone for Data Communication

RS232, as a longstanding standard for serial communication, remains widely utilized in laboratory and industrial equipment due to its simplicity, robustness, and compatibility. For microhardness testers like the HVS-1000A, RS232 enables direct, real-time data communication to connected systems such as LIMS. Key advantages include:

- Stable and Noise-Resistant Transmission: RS232’s differential signaling minimizes data corruption in industrial environments.

- Compatibility: Universally supported across many equipment and software platforms, simplifying integration efforts.

- Real-Time Data Streaming: Allows immediate uploading of measurement results after each test.

These technical benefits make RS232 pivotal in establishing a reliable bridge between microhardness testing equipment and LIMS repositories.

Integrating RS232 with LIMS: Streamlining Data Flow and Security

The process of embedding RS232 data streams into LIMS encompasses several crucial technical steps designed to enforce data integrity and operational efficiency:

- Standardized Data Formatting: Test results are exported in CSV or Excel formats following consistent schemas that enable smooth importing into LIMS databases.

- Real-Time Uploading: Every hardness measurement is automatically transmitted and committed to the LIMS server, enabling immediate access for authorized users.

- Anomaly Detection and Handling: Integrated algorithms flag abnormal data points (e.g., outliers beyond standard deviations), prompting operator review before acceptance.

- Multi-User Permission Controls: Role-based access ensures data is only accessible or modifiable by personnel with requisite credentials, enhancing security and compliance with audit requirements.

- Traceability Records: Each test and modification logs metadata including timestamps, operator IDs, and instrument calibration states, facilitating full data provenance.

Collectively, these features form a robust digital ecosystem supporting the laboratory’s data governance policies and quality assurance workflows.

Practical Application: Enhancing Research Laboratories and Third-Party Testing Efficiency

A recent deployment of the HVS-1000A microhardness tester integrated via RS232 into a university’s LIMS demonstrated significant operational gains. The laboratory reported:

- 25% Reduction in data entry time per test batch

- 99.8% Data Accuracy validated through automated anomaly detection

- Improved Collaboration: Multiple research groups accessed centralized data repositories without delays

These efficiencies translated into faster publication cycles and enhanced confidence in experimental outcomes. Similarly, third-party testing agencies appreciated the enhanced traceability aiding regulatory compliance.