In the world of material testing and precision cutting, efficiency and accuracy are paramount. The Laizhou Jincheng DS - 600 Cutting Machine emerges as a game - changer, designed to address the complex challenges faced by various industries. This article delves into the core functions of the DS - 600, its industry adaptability, and how it outperforms ordinary cutting equipment.

The DS - 600 is equipped with a four - fixture positioning system, a high - precision spindle, and an unattended limit switch design. These features make it an ideal choice for laboratory research, electronic manufacturing, and the jewelry and crystal industry. In laboratory research, where precision is crucial for accurate results, the four - fixture positioning system ensures that the material is held firmly in place, reducing errors during the cutting process. The high - precision spindle can rotate at a stable speed, enabling smooth and accurate cuts. The unattended limit switch design allows the machine to operate without constant supervision, saving time and labor costs.

In the research field, the DS - 600 helps scientists prepare high - quality samples quickly. For example, in a materials science laboratory, traditional cutting equipment may take hours to prepare a single sample, with a relatively low success rate due to inaccurate cuts. However, the DS - 600 can complete the same task in just half an hour, with a success rate of over 95%. This not only improves the efficiency of the research process but also reduces the waste of materials.

In the electronic manufacturing industry, where miniaturization and high - precision components are the norm, the DS - 600's ability to make precise cuts is invaluable. It can cut through various electronic materials such as circuit boards and semiconductor wafers with high accuracy, ensuring the quality and performance of the final products. In a large - scale electronics factory, after replacing the old cutting equipment with the DS - 600, the production efficiency increased by 30%, and the defect rate decreased by 20%.

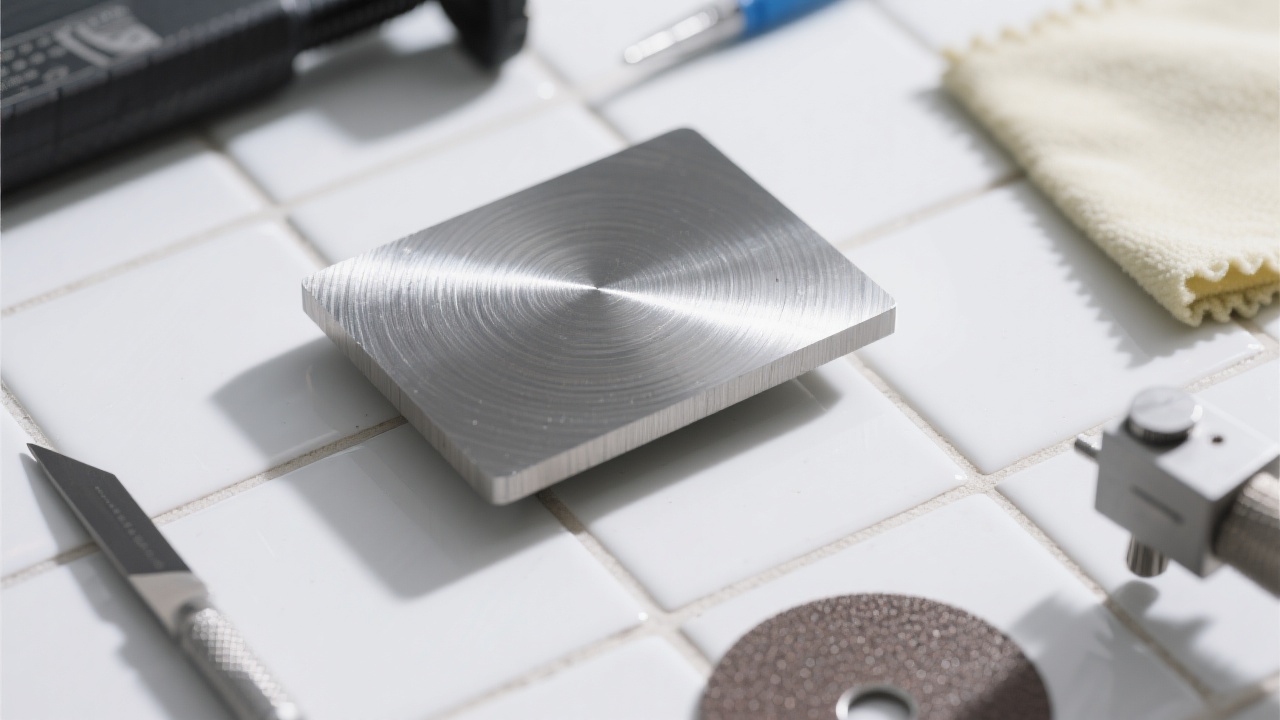

In the jewelry and crystal industry, the DS - 600 can handle delicate materials such as gemstones and crystals. Its high - precision cutting capabilities can bring out the best in these precious materials, creating beautiful and unique jewelry pieces. A well - known jewelry brand reported that after using the DS - 600, the quality of their products improved significantly, and the customer satisfaction rate increased from 80% to 90%.

Compared with ordinary cutting equipment, the DS - 600 has several distinct technical advantages. Firstly, the four - fixture positioning system provides more stable and accurate positioning than the single - or double - fixture systems used in most ordinary machines. This reduces the risk of material displacement during cutting, resulting in more precise cuts.

Secondly, the high - precision spindle of the DS - 600 can maintain a constant speed and torque, while ordinary spindles may experience fluctuations, leading to uneven cuts. The DS - 600's spindle technology ensures that every cut is of the same high quality, whether it is a small - scale sample or a large - scale production.

Thirdly, the unattended limit switch design is a feature rarely found in ordinary cutting equipment. This design allows the machine to stop automatically when it reaches the preset limit, preventing over - cutting and potential damage to the machine and the material. It also enables operators to focus on other tasks, improving overall productivity.

To make the DS - 600 more accessible to non - professionals, let's explain some of the technical terms. The limit switch is a device that can detect the position of the cutting tool and stop the machine when it reaches a certain point. This ensures the safety and accuracy of the cutting process. The fine - tuning feed refers to the ability to adjust the movement of the cutting tool in small increments. This allows for precise control of the cutting depth and width, which is especially important when working with delicate materials.

Many customers have shared their positive experiences with the DS - 600. One customer from a laboratory said, "The DS - 600 has revolutionized our sample preparation process. It is easy to operate, and the precision is outstanding. Our research progress has accelerated significantly since we started using it." Another customer from the jewelry industry commented, "The DS - 600 has helped us create more beautiful and precise jewelry pieces. Our sales have increased as a result of the improved product quality."

Data also shows significant productivity improvements. On average, users of the DS - 600 have reported a 40% increase in cutting efficiency compared to using ordinary cutting equipment. This means that more samples or products can be produced in the same amount of time, leading to higher profits and a competitive edge in the market.

We hope this article has given you a comprehensive understanding of the Laizhou Jincheng DS - 600 Cutting Machine. Do you have any questions or experiences to share? Please leave a comment below and join the discussion. If you are interested in learning more about how the DS - 600 can transform your cutting operations, click here to discover more and take the first step towards improving your productivity and quality.