-1.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

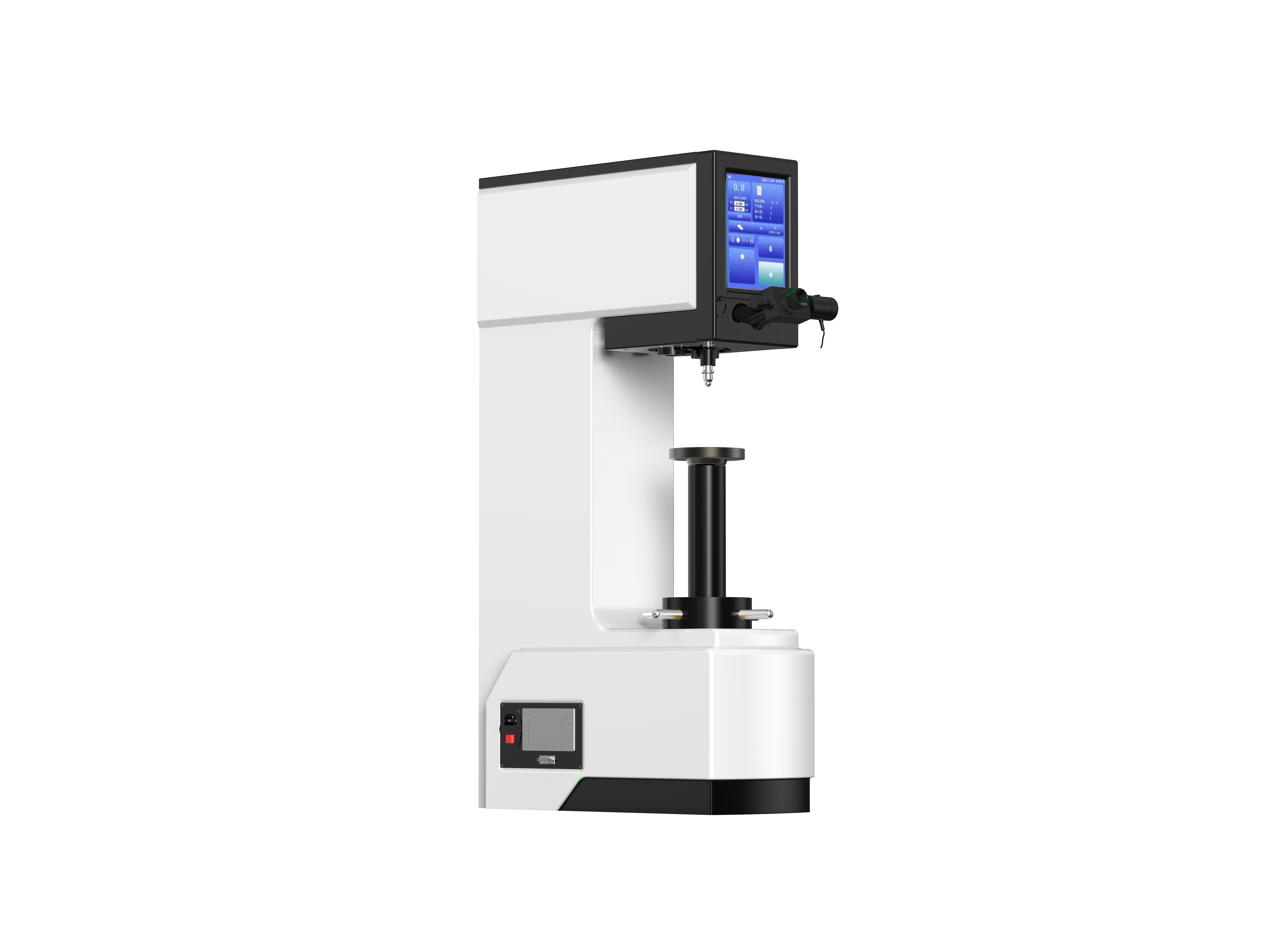

In the competitive world of international trade, ensuring product quality is pivotal to maintaining and expanding market share. The hardness tester—a vital instrument for measuring material resistance to deformation—is a cornerstone in quality control across various industries. Understanding how hardness testers operate and selecting the appropriate type can significantly boost an exporter’s product reputation and overall competitiveness.

The journey of hardness testers reflects remarkable technological progress. Early devices were rudimentary, often relying on simple scratch or indentation methods with limited accuracy. Modern hardness testers have evolved into precision instruments employing diverse testing principles, such as indentation depth, rebound velocity, and ultrasonic waves, capable of delivering highly reliable data across materials ranging from soft plastics to hardened steels. This advancement not only improves measurement efficiency but also fosters trust among global buyers by ensuring product consistency.

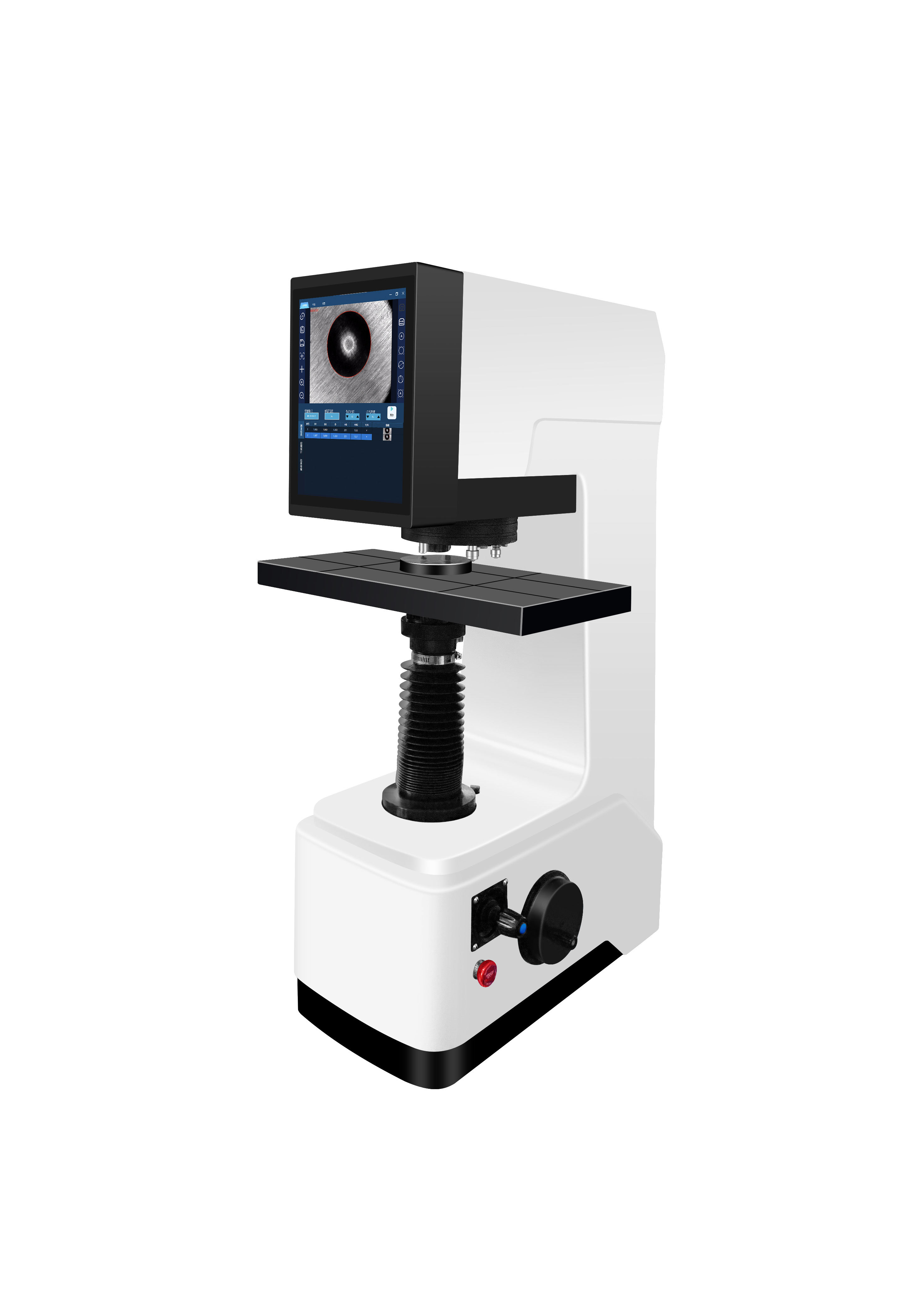

Fundamentally, hardness testers work by pressing a shaped indenter—commonly made of diamond or hardened steel—against the material's surface under a specific load. The interaction between the indenter (or probe) and the material reveals its resistance to deformation, quantified through various scales like Rockwell, Brinell, or Vickers. Each testing method involves different indenters, loads, and measurement parameters tailored to the tested material’s nature.

-1.jpg)

Different industries demand hardness testers specialized for their unique materials and operational environments:

| Hardness Test Method | Suitable Materials | Common Applications |

|---|---|---|

| Rockwell Hardness Test | Metals, Alloys, Hardened Steel | Automotive parts, machinery components |

| Brinell Hardness Test | Castings, Forgings, Non-ferrous Metals | Construction, heavy machinery, metal sheets |

| Vickers Hardness Test | Thin Materials, Micro-components | Electronics, precision instruments |

| Leeb Rebound Hardness Test | Large parts, Welds, In-service components | Field inspections, maintenance, quality assurance |

Consider a steel manufacturer targeting export markets in Europe and North America. By integrating high-precision Rockwell and Brinell hardness testers into their quality control line, they can consistently verify hardness specifications critical for mechanical performance. This robust validation minimizes product returns and strengthens brand credibility abroad.

Similarly, a precision electronics firm relies on Vickers micro-hardness testers to ensure delicate components meet stringent standards. The ability to pinpoint material weaknesses early translates directly into reliable products that satisfy international regulatory bodies and clients alike.

A well-chosen hardness tester not only ensures compliance with customer requirements but also streamlines production processes, reduces scrap rates, and accelerates time-to-market. These benefits are crucial in maintaining competitive pricing and consistent quality on the global stage.

Moreover, exporters equipped with advanced hardness testing technologies can provide detailed certification and traceability reports, enhancing client trust. This added value is often a deciding factor when buyers select suppliers in high-stakes industries such as aerospace, automotive, and heavy machinery.

To optimize your export strategy, consider these questions:

Your answers can guide a targeted investment in hardness testing equipment that ensures product excellence and enhances export competitiveness.

Ready to elevate your export quality with the perfect hardness tester? Discover top-performing hardness testing solutions now!