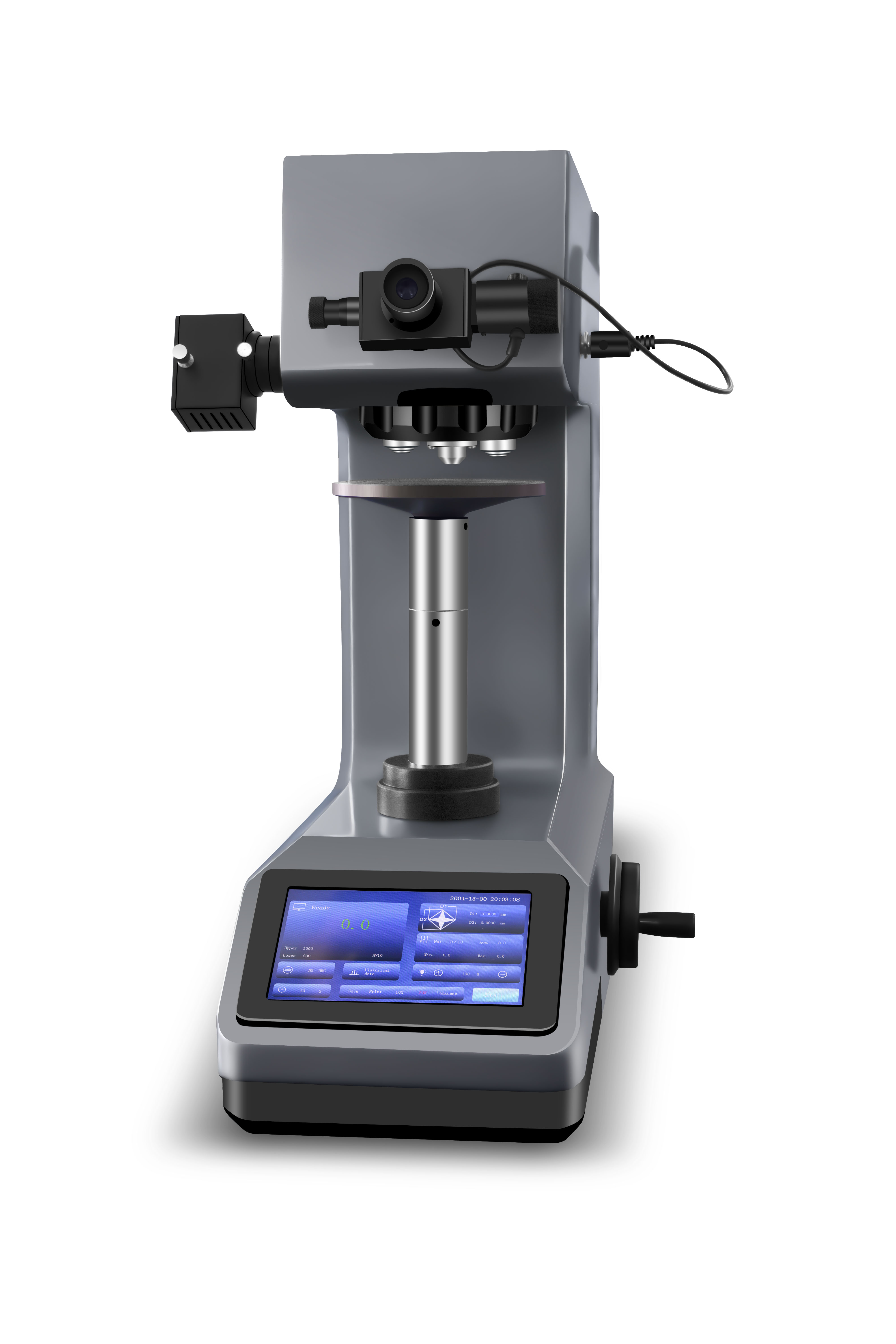

Hardness-Tester7MHVS-1000A-1.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

Hardness testers have come a long way since their inception. In the early days, hardness testing was a rather rudimentary process. Simple tools were used to make rough estimates of a material's hardness. As technology advanced, so did the sophistication of hardness testers. From basic mechanical devices to high - precision digital instruments, the evolution has been remarkable. These improvements have allowed for more accurate and consistent hardness measurements, which are crucial in various industries.

Hardness-Tester7MHVS-1000A-1.jpg)

The core of a hardness tester's operation lies in the interaction between the indenter and the material being tested. The indenter, which can be made of different materials and have various shapes (such as pyramids, spheres, or cones), is pressed into the material under a specific load. When the indenter makes contact with the material, the material deforms. The amount of deformation depends on the material's hardness. Softer materials will deform more easily, resulting in a larger indentation, while harder materials will resist deformation, leading to a smaller indentation.

After the indenter is removed, the size of the indentation is measured. This measurement is then used to calculate the material's hardness value. Different hardness scales, such as Rockwell, Brinell, and Vickers, have their own specific methods for measuring and calculating hardness based on the indentation size. For example, in the Vickers hardness test, the diagonal length of the square - shaped indentation is measured, and the hardness value is calculated using a specific formula.

| Hardness Testing Method | Principle Difference | Applicable Materials |

|---|---|---|

| Rockwell | Measures the depth of indentation under a major load after a minor load is applied first. | Metals, alloys, and some plastics |

| Brinell | Uses a hard spherical indenter to create an indentation, and the hardness is calculated based on the diameter of the indentation. | Castings, forgings, and other large - grained materials |

| Vickers | Employs a square - based pyramid indenter, and the hardness is determined by measuring the diagonal of the indentation. | Metals, ceramics, and thin - film materials |

Hardness testers play a vital role in modern industry. In the automotive industry, hardness testing is used to ensure the quality of engine components, gears, and axles. For example, engine pistons need to have the right hardness to withstand high - pressure and high - temperature environments. In the aerospace industry, hardness testing is crucial for materials used in aircraft structures and turbine blades. These components need to be extremely hard and durable to ensure flight safety. In the manufacturing of consumer electronics, hardness testing helps to ensure the quality of materials used in casings and internal components.

We invite you to share your experiences with hardness testing in your industry. Do you have any unique applications or challenges? Leave your comments below and let's start a discussion. If you're interested in learning more about our high - quality hardness testers or have any questions, feel free to contact us. We're here to provide you with the best solutions for your hardness testing needs.