Achieving high-quality metallographic samples requires more than skilled operators; it demands a rigorous approach integrating standardized procedures, meticulous equipment upkeep, and controlled environments. Variability in sample preparation can significantly impair metallurgical analysis, causing inconsistent data and unreliable results. This comprehensive guide explores the trio of critical factors—human operation error, equipment condition fluctuations, and environmental influences—that affect sample consistency. By implementing systematic maintenance, calibration routines, and stringent operational protocols, laboratories and industrial quality departments can secure repeatable and reliable surface preparations, enhancing both research validity and production quality control.

Human factors introduce noticeable variability during metallographic sample preparation. Inconsistent pressure application, deviations from specified polishing durations, or incorrect rotation speeds can lead to surface irregularities affecting microstructural clarity. For instance, a 10% deviation in rotational speed from the standardized 300 RPM can alter abrasive action, impacting surface roughness. Training operators to adhere strictly to standardized protocols curbs these inconsistencies. Utilizing visual guides, video demonstrations, and real-time digital displays for speed and time durations improve compliance. Furthermore, incorporating checklists into daily workflows ensures procedural uniformity across shifts and personnel.

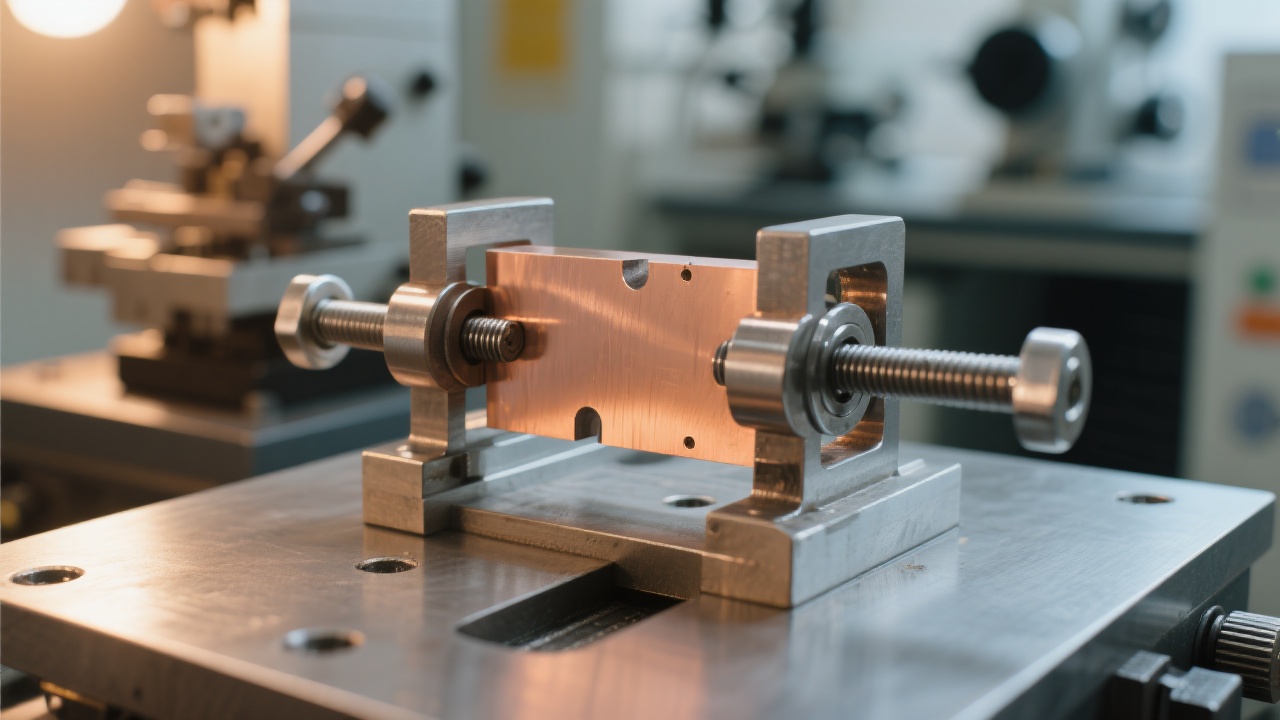

Maintaining grinding and polishing equipment in peak condition directly correlates with output stability. Periodic calibration—ideally monthly or per manufacturer guidance—helps sustain accurate rotational speeds and torque settings. Neglecting calibration can result in up to a 15% reduction in polishing uniformity, introducing sample variability. Precision calibration tools or vendor services can verify machine performance, ensuring adherence to OEM specifications.

Regular cleaning of grinding wheels and polishing pads removes residual debris and abrasive buildup, which otherwise degrade surface quality. Recommended is a daily wipe-down with appropriate solvents, followed by inspection for wear and tear including micro-cracks or uneven surfaces. Lubrication of moving parts minimizes friction and prevents premature component failure, while sealing mechanisms require biweekly checks to prevent dust ingress. Introducing digital fault detection and alert systems can further pre-empt equipment downtime, enhancing reliability.

Environmental factors such as temperature, humidity, and airborne particulates considerably impact sample preparation consistency. Optimal temperature ranges between 20°C to 25°C with relative humidity maintained at 45-55% support stable adhesive and abrasive behavior during polishing. Excess humidity can cause premature pad degradation and sample swelling, while dust and particulate contamination alter surface integrity.

Labs should invest in climate control systems and HEPA filtration to mitigate airborne contaminants. Regular environmental monitoring using data loggers provides actionable insights, enabling timely adjustments before deviations affect results. Clear signage and restricted access during critical workflows further preserve conducive conditions.

Implementing a written maintenance schedule clarifies responsibilities and timelines. A typical monthly checklist includes:

Case studies reveal that overlooked maintenance often leads to uneven polishing marks, sample overheating, or unexpected equipment stoppage. Recording these incidents and response actions builds a knowledge base, helping prevent recurrence and supporting continuous improvement protocols.

Integrating top-tier equipment is pivotal for consistency and quality assurance. The MP-2S Dual-Disc Manual Grinding & Polishing Machine from Laizhou Jincheng Industrial Equipment Co., Ltd. embodies reliability and precision, designed to minimize operational variability while facilitating comprehensive maintenance routines. Featuring user-friendly controls, rapid speed adjustment, and robust construction, it supports both high-throughput quality control and demanding research environments.