As a laboratory manager or technician, you know how critical it is to maintain the reliability and consistency of your grinding and polishing machines—especially in fields like metallurgy and new materials research where sample precision is paramount. Frequent breakdowns, inconsistent results, or unexpected downtime can disrupt workflows and inflate costs. What if a structured maintenance plan could drastically reduce these issues?

Your machine’s fiberglass (FRP) body provides durability and resistance against many chemical agents commonly used in laboratories, but it is not invincible. Residue buildup, harsh cleaning agents, or mechanical impacts can degrade its surface, leading to corrosion and structural weakening.

Maintenance Tip: Clean the machine body daily with non-abrasive, pH-neutral detergents. Avoid acidic or alkaline solvents that can damage the FRP surface. Regularly inspect for cracks or discoloration that can signal early corrosion.

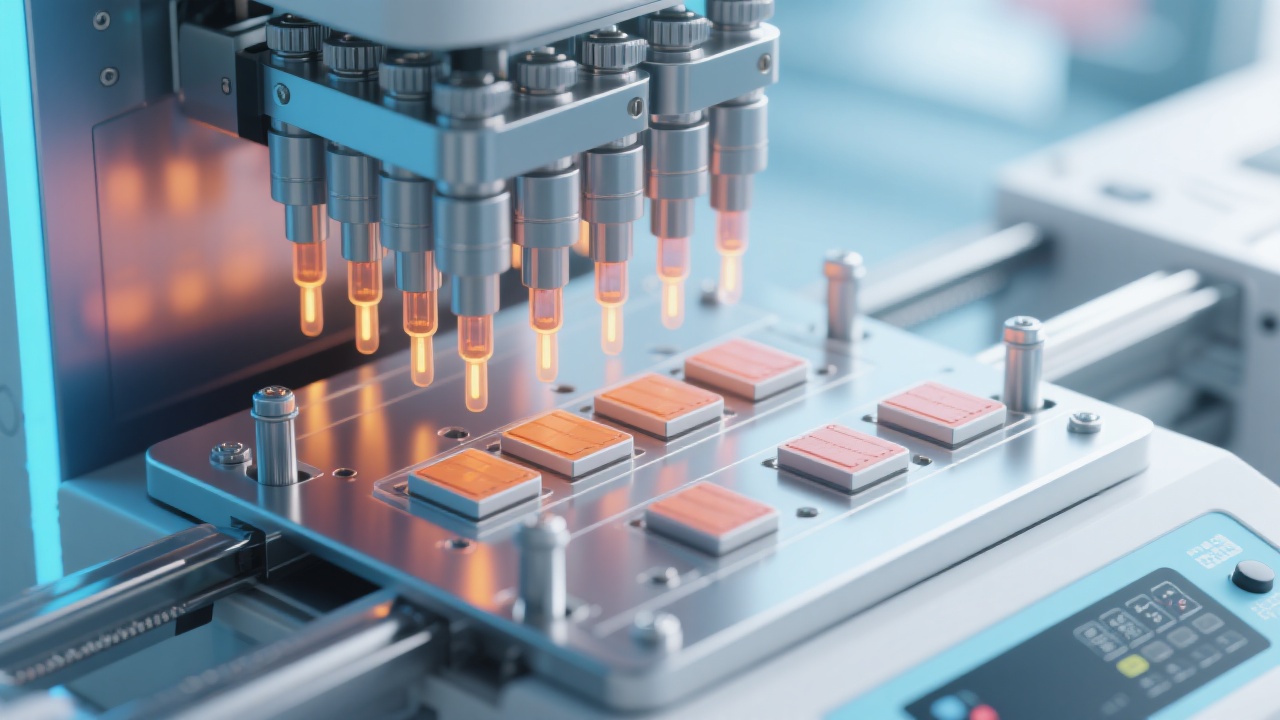

The heart of your grinder-poler is its speed control and motor system, typically consisting of precision gears and an electric motor. Proper lubrication minimizes friction and wear, while efficient heat dissipation protects against motor overheating that could cause shutdowns or damage.

Actionable Steps:

Residual polishing compounds, metal dust, or moisture accumulation can degrade machine parts or contaminate samples. Adhering to a strict daily cleaning routine keeps internal components free from grime, extending usable life and maintaining sample integrity.

Checklist:

Regular inspections and calibration are essential for ensuring operational accuracy and preventing drift in polishing thickness or grinding speeds. Calibration intervals may vary depending on usage intensity but should never be neglected.

| Maintenance Task | Recommended Frequency | Notes |

|---|---|---|

| Visual & Functional Inspection | Monthly | Check wear parts & electronic components |

| Lubrication of Moving Parts | Quarterly | Use original manufacturer lubricants for best performance |

| Calibration of Speed & Pressure Settings | Every 6 Months or After Major Repairs | Ensures sample preparation consistency |

Different industries impose varying load and operational frequencies on grinding and polishing machines. For example:

Adjust maintenance schedules accordingly to align with operational demands, reducing unexpected failures and improving reproducibility of results.

Have you encountered unexpected downtime with your grinding and polishing machine? Share your experience and solutions in the comments below to help build a knowledge community.