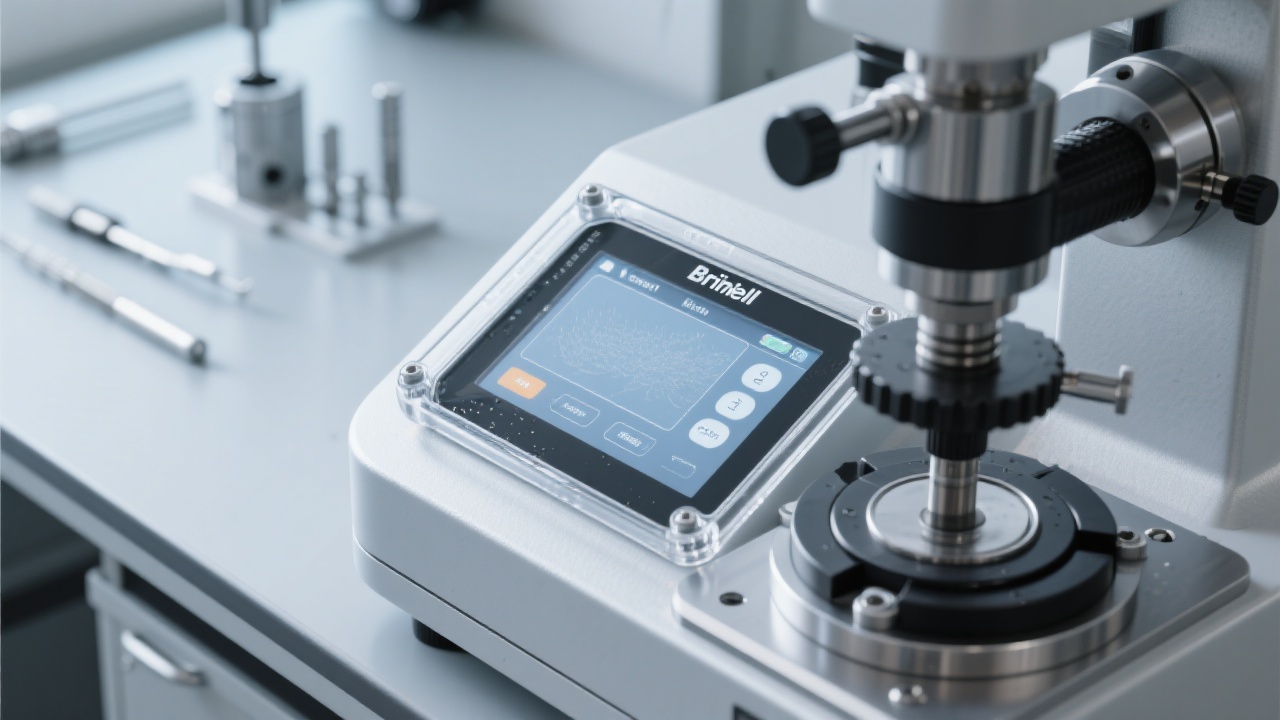

Precision cutting machines play an indispensable role in the field of material testing, where cutting accuracy and operational efficiency directly influence the reliability of test results. Selecting an optimal cutting device requires understanding several critical elements that govern both performance and usability in real-world lab and industrial environments.

Material testing setups demand equipment that can achieve exceptionally high precision to avoid sample distortion or damage. Cutting errors as small as ±0.01 mm may skew analytical outcomes, impacting subsequent research conclusions or quality control decisions. Therefore, a cutting machine’s ability to maintain consistent dimensional integrity is non-negotiable.

Factors impacting precision include:

While accuracy is crucial, throughput cannot be ignored, especially for laboratories or production lines facing high-volume demand. Efficient cutting reduces cycle times and improves overall productivity without compromising quality.

Key performance metrics to assess include:

| Technical Parameter | Impact on Efficiency | Performance Threshold |

|---|---|---|

| Spindle Speed (RPM) | Higher speed enables faster cutting but must balance heat generation | Up to 6000 RPM for DS-600 |

| Automation Level (e.g., limits & auto-stop) | Reduces manual intervention, decreases downtime | Fully automatic cut-stop ensures zero operator errors |

| Fixture Adjustable Range | Allows quick setup for diverse sample sizes | Up to ±10 mm fine adjustment |

Taking the DS-600 as a benchmark, this model exemplifies the optimal balance between precision and productivity in contemporary material test cutting.

"Compliance with standards such as ISO 9001 and ASTM test methods ensures that precision cutting equipment not only meets performance criteria but also maintains safety and repeatability across different labs worldwide."

Brands like the DS-600 align with such certifications guaranteeing users that every cutting cycle adheres to stringent global quality protocols—critical when test results support product developments or regulatory decisions.

Effective procurement should stem from clearly identifying cutting pain points—be it inconsistency, slow throughput, or excessive manual setup—and matching these with equipment that excels in corresponding technical areas.

| Common Pain Point | Recommended Feature | DS-600 Advantage |

|---|---|---|

| Inaccurate Sample Positioning | High precision adjustable fixture | ±0.01 mm fixture accuracy |

| Operator-dependent Errors | Automated limit switches and stop functions | Full automation reduces manual interference |

| Low Throughput | High RPM spindle with stable torque | Up to 6000 RPM, optimized for speed & quality |

Choosing a precision cutting machine like the DS-600, designed with advanced automation, high-precision mechanics, and international quality certifications, sets a foundation for trustworthy and scalable material testing workflows.

Explore how the DS-600 precision cutting machine can transform your lab or production line—boosting both result fidelity and processing speed with minimal operator dependency.