As a critical tool in material analysis, metallographic cutting machines play an essential role in various industries such as mechanical manufacturing, metallurgy, chemical processing, and power generation. Choosing the right equipment can significantly enhance work efficiency and product quality. This technical guide provides insights into the key selection points for metallographic cutting machines and highlights the advantages of the LaiZhou JinCheng Q-2 manual metallographic sample cutting machine.

In the automotive industry, precision is crucial for analyzing the microstructure of engine components. A leading manufacturer in Germany reported a 25% increase in production efficiency after upgrading their metallographic cutting system. Similarly, in the steel industry, metallographic cutting machines are used to examine the internal structure of alloys, ensuring compliance with international standards.

According to a recent survey by the International Materials Research Association, over 70% of industrial laboratories rely on metallographic cutting machines for sample preparation. These devices not only improve accuracy but also reduce the time required for sample preparation by up to 40%.

Metallographic cutting machines are widely used in the following fields:

| Industry | Application | Benefits |

|---|---|---|

| Mechanical Manufacturing | Analysis of gear and bearing materials | Improved quality control and durability testing |

| Metallurgy | Examination of alloy structures | Enhanced material performance and safety |

| Chemical Processing | Testing of corrosion-resistant materials | Longer service life and reduced maintenance costs |

| Power Generation | Inspection of turbine and generator components | Increased operational reliability and energy efficiency |

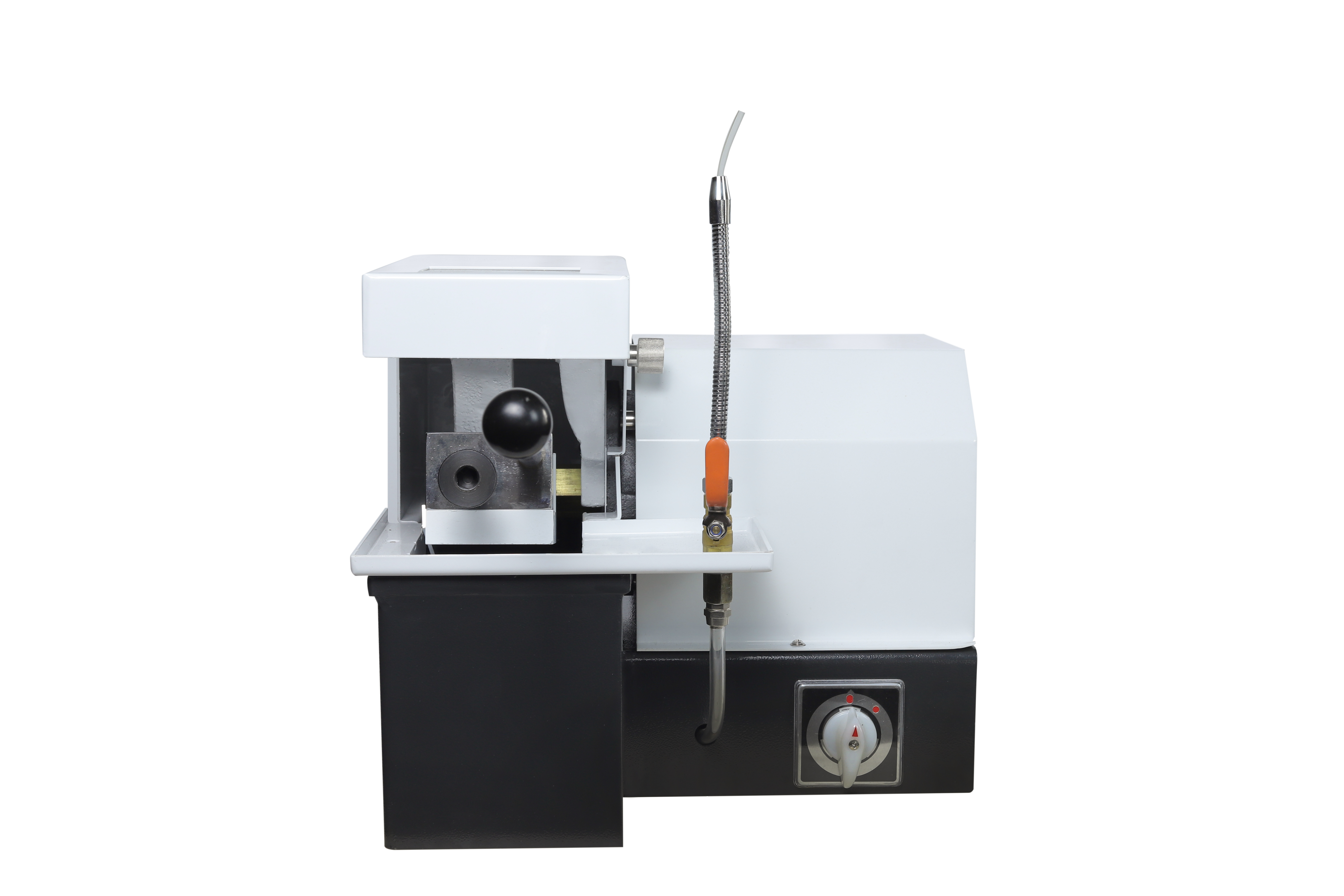

The LaiZhou JinCheng Q-2 is a high-performance manual metallographic cutting machine designed for precision and durability. It features a stable cutting platform, adjustable speed settings, and a user-friendly interface. Compared to many domestic alternatives, this model offers superior stability and accuracy, making it ideal for laboratories and industrial environments.

With a maximum cutting capacity of 100 mm, the Q-2 is suitable for a wide range of sample sizes. Its ergonomic design reduces operator fatigue, while its robust construction ensures long-term use without compromising performance. According to customer feedback, this machine has improved sample preparation efficiency by up to 35% in multiple applications.

When selecting a metallographic cutting machine, consider the following factors:

Based on industry data, the LaiZhou JinCheng Q-2 outperforms many competitors in terms of accuracy, ease of use, and cost-effectiveness. It is a top choice for laboratories and manufacturers seeking a reliable and efficient cutting solution.

Choosing the right metallographic cutting machine is crucial for optimizing your workflow and ensuring accurate results. The LaiZhou JinCheng Q-2 offers a balance of performance, reliability, and value that makes it an excellent option for various industries. By understanding the key selection criteria, you can make an informed decision that meets your specific needs and enhances overall productivity.

Ready to upgrade your sample preparation process? Explore the LaiZhou JinCheng Q-2 today and take the first step toward greater efficiency and precision.