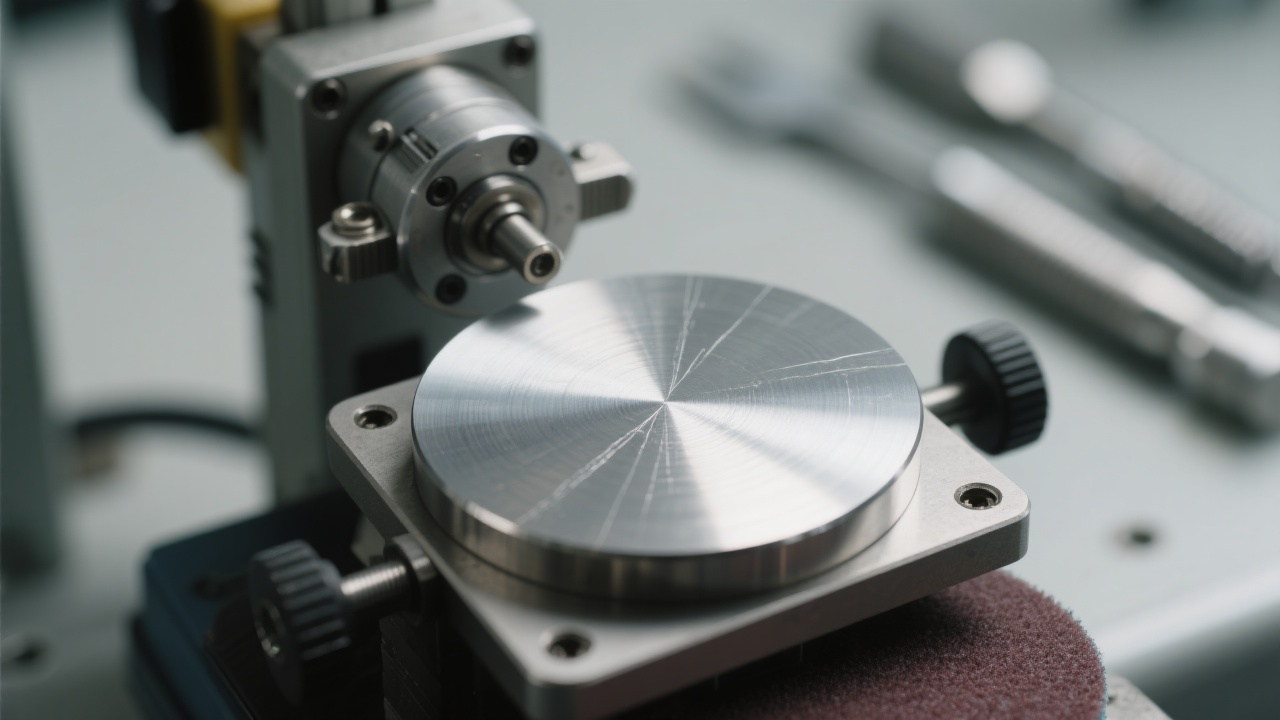

In the metallurgical industry, laboratory grinding and polishing equipment is used intensively. The MP-2S double-disc manual grinding and polishing machine, a popular choice among global customers, requires meticulous maintenance to ensure long - term stable operation. This article provides a comprehensive guide on its maintenance, aiming to help laboratory managers and technicians reduce equipment failure rates and enhance the reliability of scientific research data.

The MP - 2S is equipped with a Fiberglass Reinforced Plastic (FRP) body, known for its excellent corrosion resistance. This characteristic is particularly beneficial in metallurgical and new materials research laboratories, where chemical substances are often used. However, even with its corrosion - resistant nature, daily cleaning and proper maintenance are essential.

Regularly clean the FRP body with a mild detergent solution to remove any chemical residues or dust. Pay special attention to the corners and edges, as these areas are often overlooked. A weekly cleaning routine can significantly extend the lifespan of the body, reducing the risk of corrosion - related damage. This simple yet effective maintenance step is crucial for the overall durability of the equipment, helping you save on replacement costs in the long run.

The variable - speed control system of the MP - 2S, including gear lubrication and motor heat dissipation, is the heart of the machine's operation. Improper maintenance of this system can lead to transmission failures, which can disrupt laboratory work and cause costly downtime.

For gear lubrication, use high - quality lubricants recommended by the manufacturer. Lubricate the gears every 50 operating hours to ensure smooth operation. Regarding motor heat dissipation, regularly check the cooling fans and vents. If the vents are blocked, the motor temperature can rise rapidly, leading to premature motor failure. Clean the vents monthly to maintain optimal heat dissipation, which will contribute to the long - term stability of the variable - speed control system.

A well - designed standardized inspection checklist is the key to efficient equipment maintenance. Different industries have different usage intensities, so the checklist should be tailored to meet these specific requirements.

For high - intensity usage in large - scale metallurgical laboratories, a daily inspection of the key components such as the grinding discs and the control panel is recommended. In medium - intensity usage scenarios like new materials research laboratories, a weekly comprehensive inspection can be sufficient. The checklist should cover all aspects of the equipment, from the body to the control system, ensuring that no potential issues are overlooked.

Correct operating habits play a vital role in extending the lifespan of the core components of the MP - 2S. In real - world laboratory scenarios, improper operation can cause excessive wear and tear on the grinding discs and other parts.

For example, starting the machine with excessive load can damage the motor and gears. Always follow the recommended start - up and shut - down procedures. Additionally, using the correct grinding and polishing materials and parameters can also reduce the stress on the components, ensuring consistent sample preparation and reliable scientific research data.

Tip 1: Avoid using abrasive cleaners on the FRP body, as they can scratch the surface and reduce its corrosion resistance.

Tip 2: Do not ignore small noises or vibrations during operation, as they may indicate early signs of component failure.

Tip 3: Do not exceed the recommended load capacity of the machine, which can severely damage the internal components.

Here is a simple maintenance flowchart to help you better understand the maintenance process of the MP - 2S:

By following these maintenance guidelines, you can significantly enhance the longevity and reliability of your MP - 2S double - disc manual grinding and polishing machine, ultimately contributing to more efficient and reliable quality control in your laboratory.

Take control of your equipment maintenance today! Our high - quality MP - 2S double - disc manual grinding and polishing machines are deeply trusted by global customers. If you have any questions or need further maintenance advice, contact us now to ensure your laboratory equipment runs stably and efficiently.