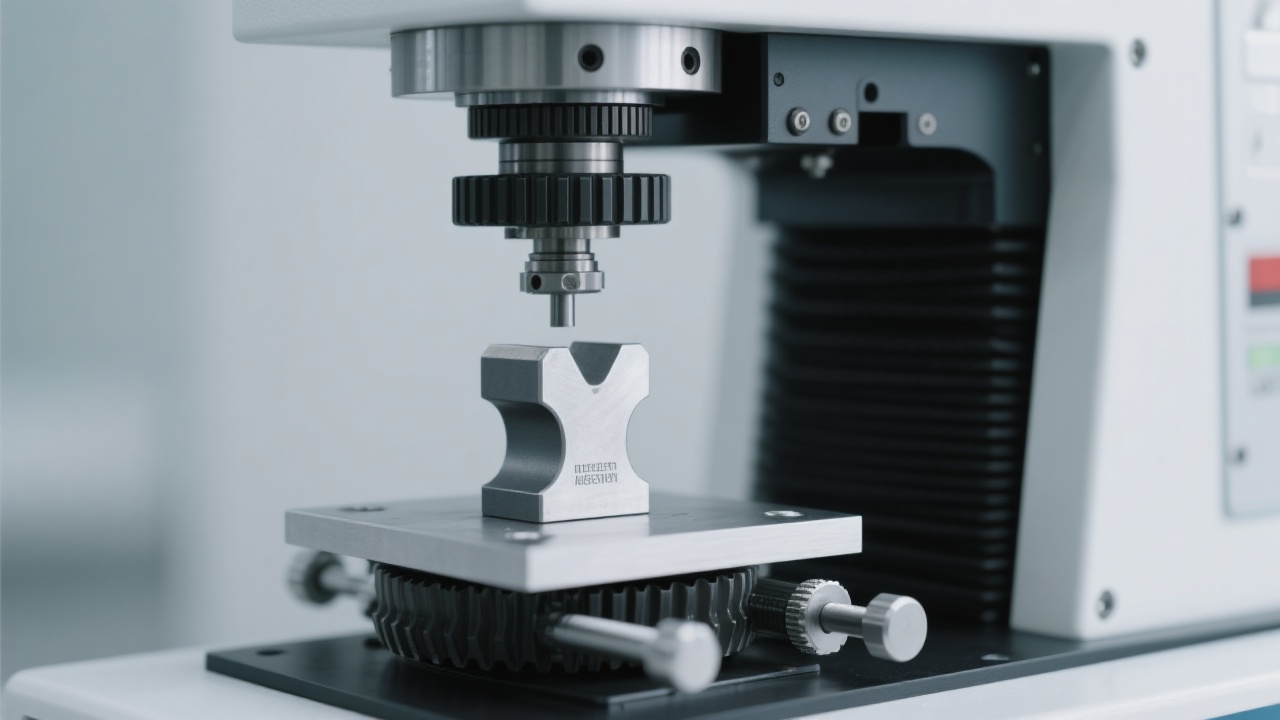

The precision and reliability of microhardness testing serve as a cornerstone for scientific research, quality control in manufacturing, and materials engineering. Yet, laboratories and testing facilities frequently encounter challenges in managing the extensive data generated by advanced microhardness testers. Efficient data transmission, traceability, and integrity are crucial for audit compliance and customer acceptance, especially when multiple users and complex workflows are involved.

RS232 serial communication remains a robust and widely adopted protocol for connecting microhardness testers to laboratory information management systems (LIMS). The interface enables direct, real-time transmission of measurement data from devices, minimizing manual input errors and expediting workflow. Its simplicity translates into stable bi-directional data exchange under industrial conditions, with typical baud rates ranging from 9600 to 115200 bps ensuring timely data delivery. Field applications demonstrate that properly configured RS232 connections reduce data lag by up to 30% compared to manual entry.

LIMS integration represents a transformative step toward automating microhardness data workflows. By capturing measurement results directly from test instruments via RS232, LIMS centralizes data storage, contextualizes metadata, and facilitates sophisticated analytics. Successful integration hinges on middleware capable of parsing instrument protocols and exporting data in universally compatible formats.

Exporting to a standardized CSV format stands out as the optimal solution: each test result encapsulates critical fields such as a unique sample identifier, precise measurement value, test operator ID, and ISO 17025-compliant timestamp with millisecond granularity. This structure ensures both traceability and interoperability across disparate laboratory systems and cross-organization collaborations.

Adopting consistent CSV templates dramatically improves data sharing efficiency. Key aspects include:

Furthermore, offering dual export options—CSV for machine readability and Excel for human-friendly review—empowers diverse user groups to engage effectively with the data.

Reliable data extends beyond collection—it requires rigorous validation and controlled access:

Implementing these strategies enhances stakeholder confidence and streamlines audit processes.

A case study in a leading university materials science lab demonstrated that integrating microhardness testers via RS232 into their LIMS with standardized CSV exporting reduced manual data entry errors by 85% and accelerated report generation by 40%. Collaborative research projects involving third-party labs reported improved data consistency and transparency, shortening project timelines significantly.

These outcomes underscore the critical role of digitalization in elevating scientific rigor and operational productivity.

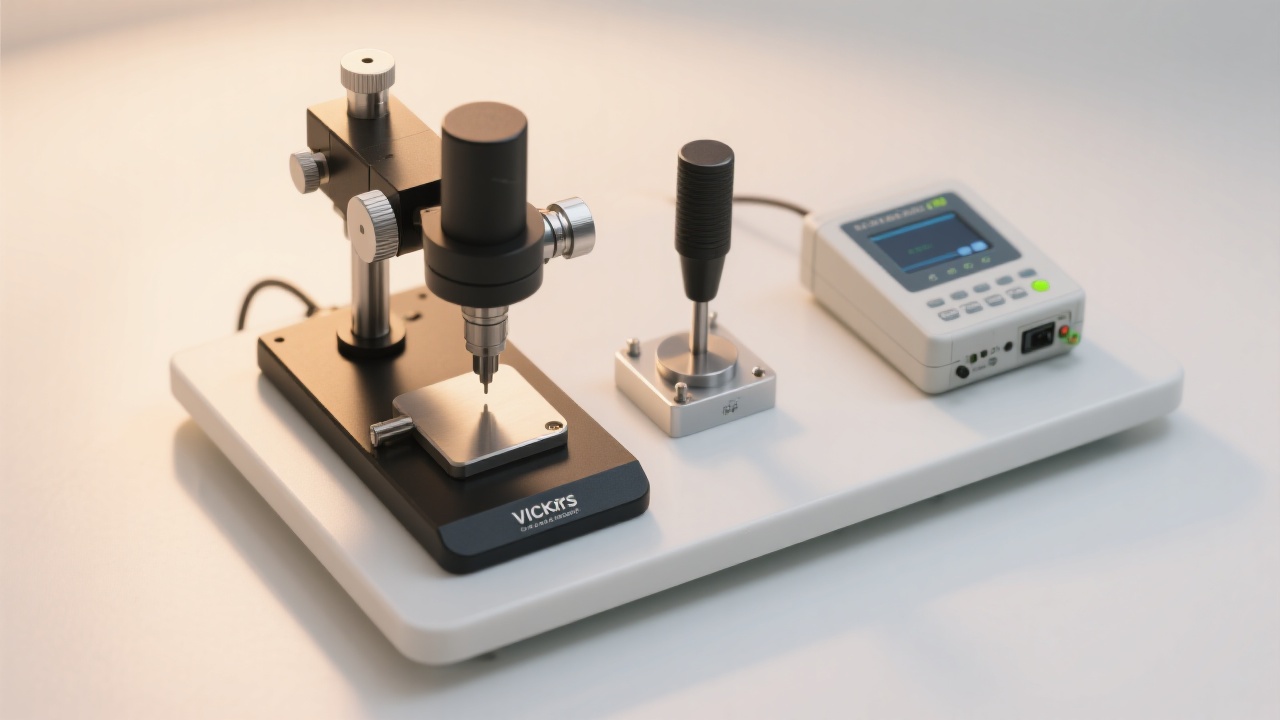

Laboratories aiming to advance their digital testing infrastructure should consider high-precision microhardness instruments compliant with ISO and ASTM guidelines. Such devices natively support RS232 output and are often bundled with software facilitating CSV-standard exports and LIMS compatibility. Adopting these integrated solutions streamlines transitions toward fully digitalized quality management systems.