Selecting Proper Test Force in Multi-Material Brinell Hardness Testing: Practical Insights for Carbon Steel and Aluminum Alloys

Accurate hardness measurement across diverse metals demands scientific selection of test force in Brinell hardness testing. This article delves into the physical principles behind test force selection for carbon steel, aluminum alloys, and other common industrial metals, aligning recommended loads with material attributes ranging from 62.5 kgf to 3000 kgf. By unpacking real-world industry applications—metallurgical plants, automotive component fabrication, and R&D labs—it offers actionable guidance to optimize test parameters, ensuring reliable data and reproducible results.

Fundamentals of Brinell Hardness Test Force Selection

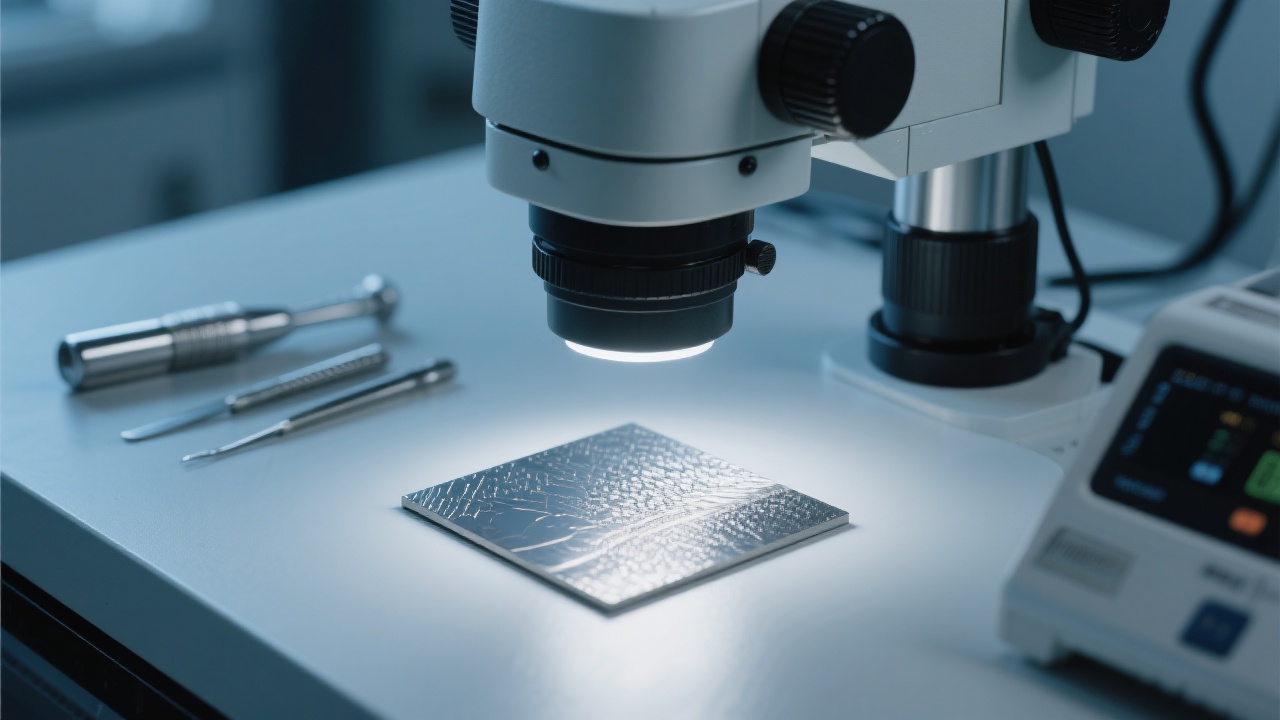

The Brinell hardness test evaluates material resistance to indentation by pressing a hardened steel or tungsten carbide ball under a specified load. The choice of test force dramatically influences the indentation diameter, surface damage, and measured hardness value. According to ISO 6506-1, the test force must be adapted to material hardness, microstructure, and intended accuracy.

For harder metals like carbon steel, widely used forces range from 500 kgf to 3000 kgf, enabling a clear, measurable indentation without over-penetration. Softer metals such as aluminum alloys typically require lower forces, from 62.5 kgf to 500 kgf, to prevent excessive deformation or cracking that compromises result fidelity.

Material-Specific Test Force Recommendations and Their Rationale

| Material Category |

Recommended Test Force (kgf) |

Physical Factors Affecting Selection |

| Carbon Steel (C45, 1045) |

500–3000 |

High hardness and structural uniformity require higher loads for clear indentations, balancing between measurable indentation diameter and avoiding microcracking. |

| Aluminum Alloys (6061, 7075) |

62.5–500 |

Low hardness and ductility into account to avoid excessive deformation or indentation flattening. |

| Copper Alloys (Brass, Bronze) |

100–500 |

Moderate hardness requiring medium test force to maintain consistent penetration without surface damage. |

| Stainless Steel (300, 400 series) |

750–3000 |

Higher hardness and work hardening potential necessitate elevated test forces for reliable measurement. |

Industry Applications: Tailoring Test Force to Real-World Contexts

In metallurgical plants, batch hardness verification prioritizes repeatability. For carbon steels used in automotive shafts and gears, test forces around 1000 to 3000 kgf are common, producing standardized indentations that reflect mechanical performance accurately.

Aluminum alloy parts in aerospace and lightweight vehicle sectors require more delicate testing at forces as low as 62.5 to 250 kgf to prevent compromising the surface integrity, ensuring the hardness values correspond to genuine material properties rather than deformation artifacts.

Case Insight: A leading automotive supplier reduced hardness testing variability by 15% after adjusting test force based on surface finish and material grade, using a digital Brinell hardness tester capable of flexible force settings, confirming the critical nature of force calibration in quality control.

Practical Hardness Test Force Selection Workflow

- Identify the material and its grade/composition.

- Review standard reference values (ISO 6506-1) and typical hardness ranges.

- Determine the surface condition (machined, polished, rough).

- Choose test force within recommended range guided by material hardness and surface type.

- Validate force selection via trial indentations, ensuring clear, measurable impressions without damage.

- Document results and adjust if excessive deviation or surface cracking occurs.

Common Misconceptions and Frequently Asked Questions

Q1: Can a single test force be used universally across all metals?

A: No. Using an unsuitable force risks invalid readings—too high damages soft metals; too low makes indentations on hard metals unmeasurable.

Q2: Does increasing test force always improve accuracy?

A: Not necessarily. Excessive force may cause surface cracks or plastic deformation, leading to inconsistent results.

Q3: How does surface preparation affect test force choice?

A: Highly polished surfaces allow more precise indentation measurement and may permit lower loads; rough surfaces require careful force selection to avoid anomalous readings.

Empower Your Quality Control with Advanced Brinell Hardness Testing Technology

Choosing the correct test force for Brinell hardness measurement is more than a technical detail—it is the backbone of material quality assurance. Implementing smart instrumentation like the HBS-3000 Digital Brinell Hardness Tester allows flexible force adjustment from 62.5 kgf up to 3000 kgf, precise indentation measurement, and compliance with international standards, streamlining your quality control workflows.

Whether verifying batch consistency in a metallurgical facility or conducting R&D on novel aluminum alloys, selecting an optimal test force ensures every hardness reading truly reflects your product’s integrity.