In the realm of materials science, accurately measuring the hardness of non-metallic materials is a crucial yet challenging task. Scientists and quality control experts often grapple with issues like unclear indentations and large data fluctuations during non-metallic material hardness testing. This article offers a comprehensive guide to the entire sample preparation process for non-metallic material hardness testing, aiming to help users avoid common pitfalls and conduct scientific hardness evaluations of new materials such as ceramics, plastics, and composites.

Non-metallic material hardness testing is fraught with typical issues that resonate with researchers and quality control professionals. For instance, unclear indentations can make it difficult to accurately measure the hardness value. In some cases, the data shows significant fluctuations, leading to poor repeatability of test results. These problems not only waste time and resources but also affect the accuracy of research and product quality control.

The indentation deformation mechanism of non-metallic materials is extremely complex compared to metallic materials. Non-metallic materials may exhibit different deformation behaviors under different loads and indentation times, such as brittle fracture, plastic deformation, and viscoelastic deformation. Understanding these complex mechanisms is crucial for accurate hardness testing.

Surface flatness has a significant impact on the accuracy of non-metallic material hardness testing. Even small surface irregularities can cause uneven stress distribution during indentation, resulting in inaccurate hardness measurements. Therefore, the surface of the test sample must be carefully prepared to ensure high flatness.

The selection of load parameters is another critical factor in non-metallic material hardness testing. Incorrect load selection can lead to over - or under - indentation, affecting the accuracy of the test results. For example, if the load is too small, the indentation may be too shallow to accurately measure; if the load is too large, it may cause excessive deformation or damage to the sample.

To address these issues, we can refer to international standards such as ISO 6508 and ASTM E18. These standards provide detailed guidelines on hardness testing methods, including the selection of indenter types and the adjustment logic of holding time.

According to ISO 6508, for non-metallic materials with different hardness levels, different indenter types are recommended. For relatively hard non-metallic materials, a diamond indenter can be used; for softer materials, a tungsten carbide indenter may be more appropriate. The holding time also needs to be adjusted according to the properties of the material. Generally, for materials with high viscoelasticity, a longer holding time is required to ensure accurate measurement.

Reference to ISO 6508: "The indenter shall be selected according to the hardness range of the test material. For materials with a hardness greater than [X] HRC, a diamond indenter shall be used; for materials with a hardness less than [X] HRC, a tungsten carbide indenter can be considered."

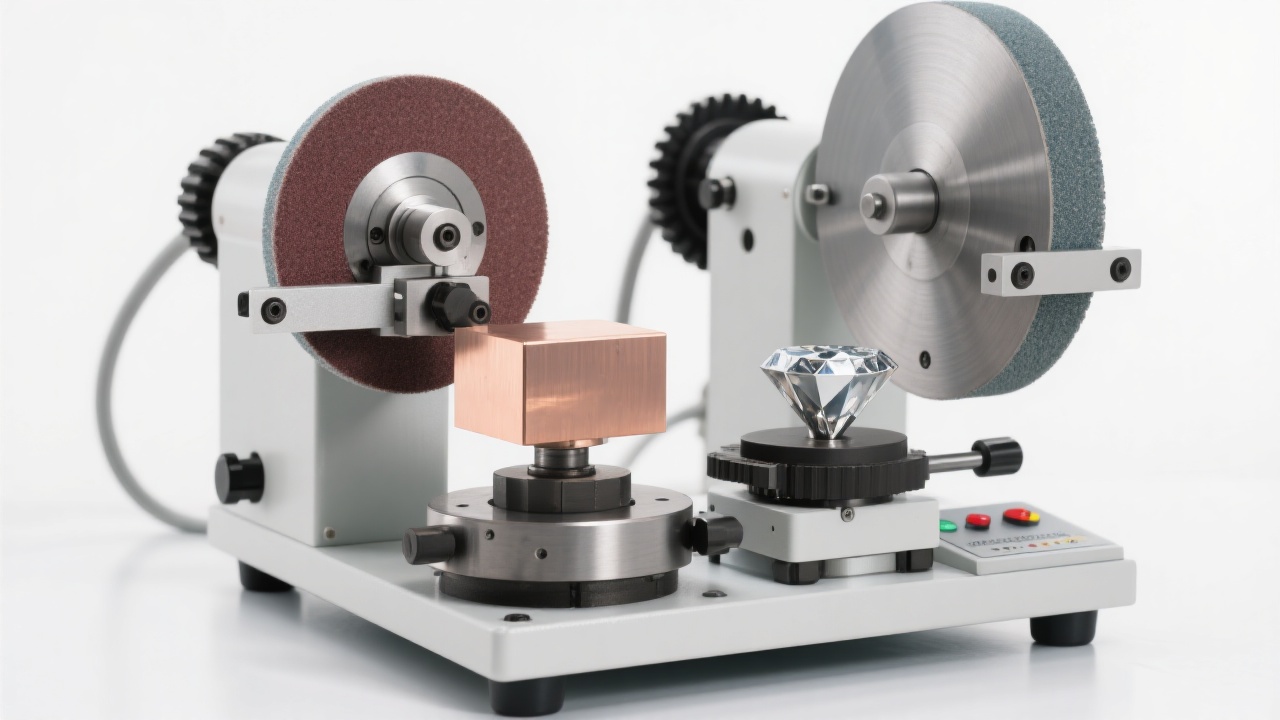

Automated equipment, such as the MHRS - 150, plays a vital role in non-metallic material hardness testing. These devices can significantly reduce human intervention and improve the consistency of multi - point measurements. By using automated equipment, the test process can be standardized, reducing the influence of human factors on test results.

Intelligent data analysis functions can also greatly enhance the efficiency of non-metallic material hardness testing. By using intelligent data systems, test data can be automatically collected, analyzed, and reported. This not only speeds up the research process but also enhances the professionalism of test reports.

For example, in a research project on a new composite material, the intelligent data system was able to quickly analyze the hardness data of hundreds of samples, identify trends, and generate detailed reports. This saved a lot of time and effort for the research team.

If you are interested in learning more about the Rockwell test parameter configuration guide suitable for your material type, please visit our technical documentation center.