In the materials testing industry, choosing the wrong cutting machine can cost time, money, and accuracy — especially when precision matters most. I’ve seen clients lose up to 15% of their sample integrity due to inconsistent cuts. One German lab, for example, was struggling with uneven test results from aluminum alloy samples until they switched to a high-precision solution.

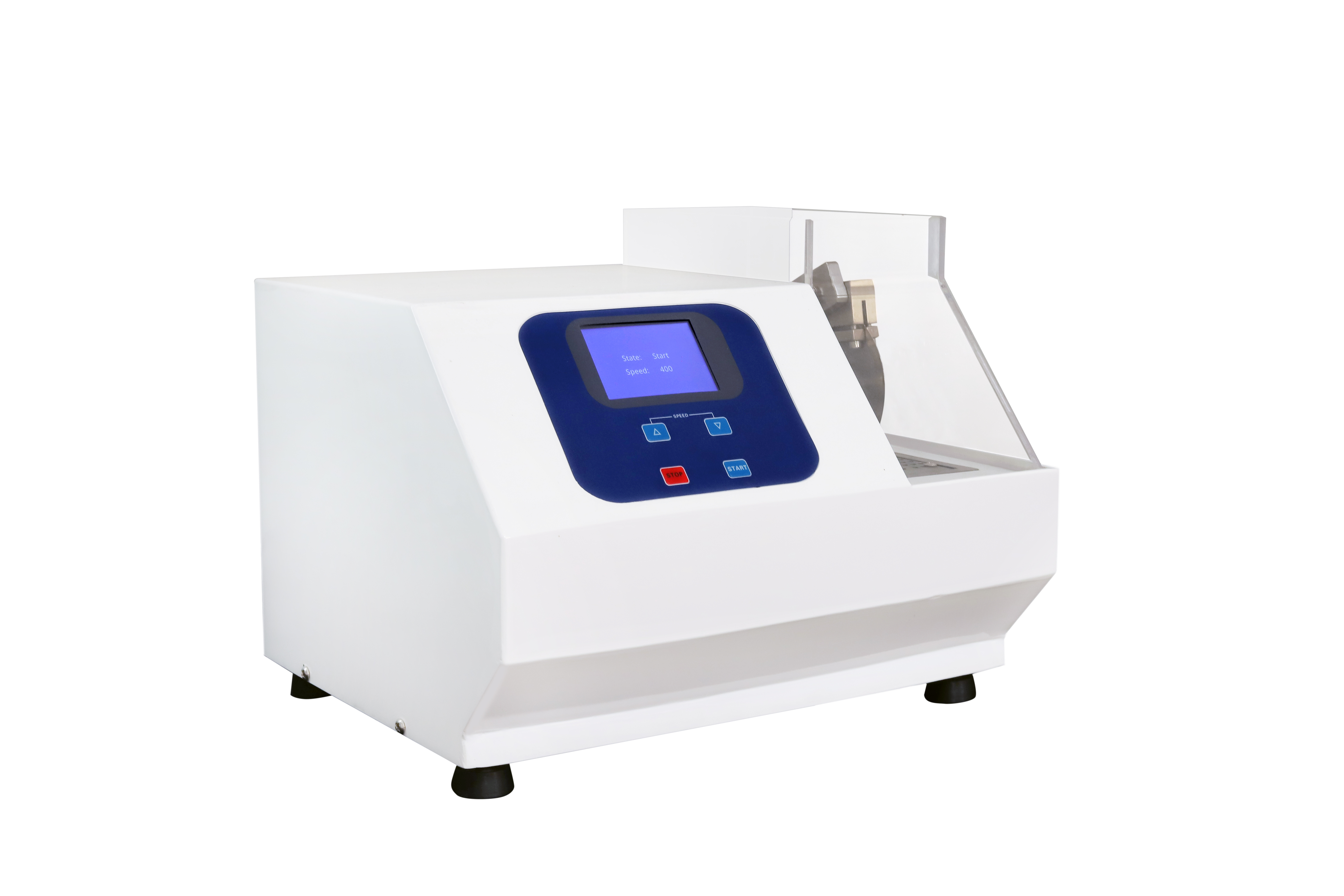

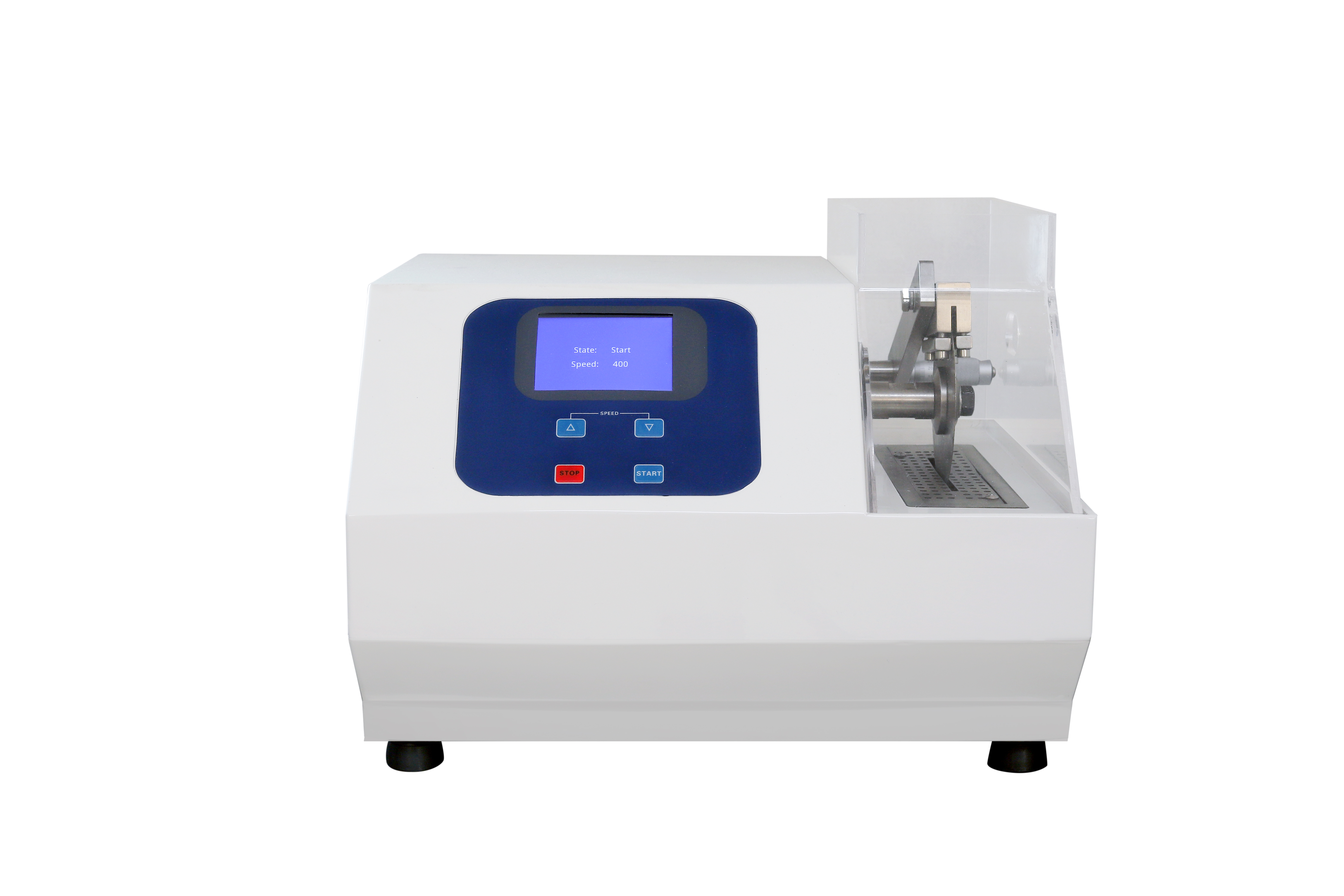

Many procurement managers assume all “precision” cutters are equal — but that’s where the problem starts. In material testing, even a 0.05mm deviation can lead to incorrect tensile strength readings or poor microstructure analysis. The DS-600 from LaiZhou JinCheng Industrial Equipment Co., Ltd. uses a four-clamp positioning system that ensures consistent alignment across multiple samples — reducing variability by over 70% in real-world tests.

Traditional machines require constant operator attention — which is not only inefficient but also risky. With the DS-600’s automatic limit switch feature, operators can set up batches and walk away. A case study from a Chinese aerospace materials lab showed a 40% reduction in labor hours per week after adopting this function. That’s not just convenience — it’s productivity optimization.

| Feature | Standard Cutter | DS-600 Precision Cutter |

|---|---|---|

| Auto Stop After Cut | No | Yes |

| Micro-adjustment for Feed Position | Manual Only | Digital + Manual |

| Unattended Operation | Not Possible | Supported |

The DS-600 doesn’t just perform well — it performs reliably. Its built-in micro-adjustment mechanism allows fine-tuning of feed position without stopping production. And once the cut is complete, it automatically stops, preventing overheating and wear. In a 6-month field test across 3 different labs, the DS-600 had zero downtime due to mechanical failure — compared to an average of 12 hours/month for standard models.

International standards like ISO 15184 (for metallic materials) and ASTM E8/E8M require repeatable, traceable measurements. The DS-600 meets these requirements out of the box — with calibration certificates included and full documentation available in English, German, Spanish, and Chinese. This makes audits easier and builds trust with global clients.

If you're still using older models that lack automation, precise control, or international compliance — you’re likely missing out on efficiency gains of at least 30%. Whether you're in automotive R&D, construction materials, or semiconductor testing, selecting the right cutter isn’t optional anymore.

Don’t let outdated equipment slow down your next big discovery. See how the DS-600 can transform your workflow — with real data, proven reliability, and smart design.

Get Your Free DS-600 Performance Comparison Report Now