In the material testing industry, the choice of a precision cutting machine can significantly impact the accuracy and efficiency of the entire testing process. Consider a case where a company selected an inappropriate precision cutting machine. They faced issues such as inaccurate cuts, low efficiency, and frequent breakdowns. This not only wasted a lot of time but also led to inaccurate test results, which ultimately affected the quality control and R & D progress of their products.

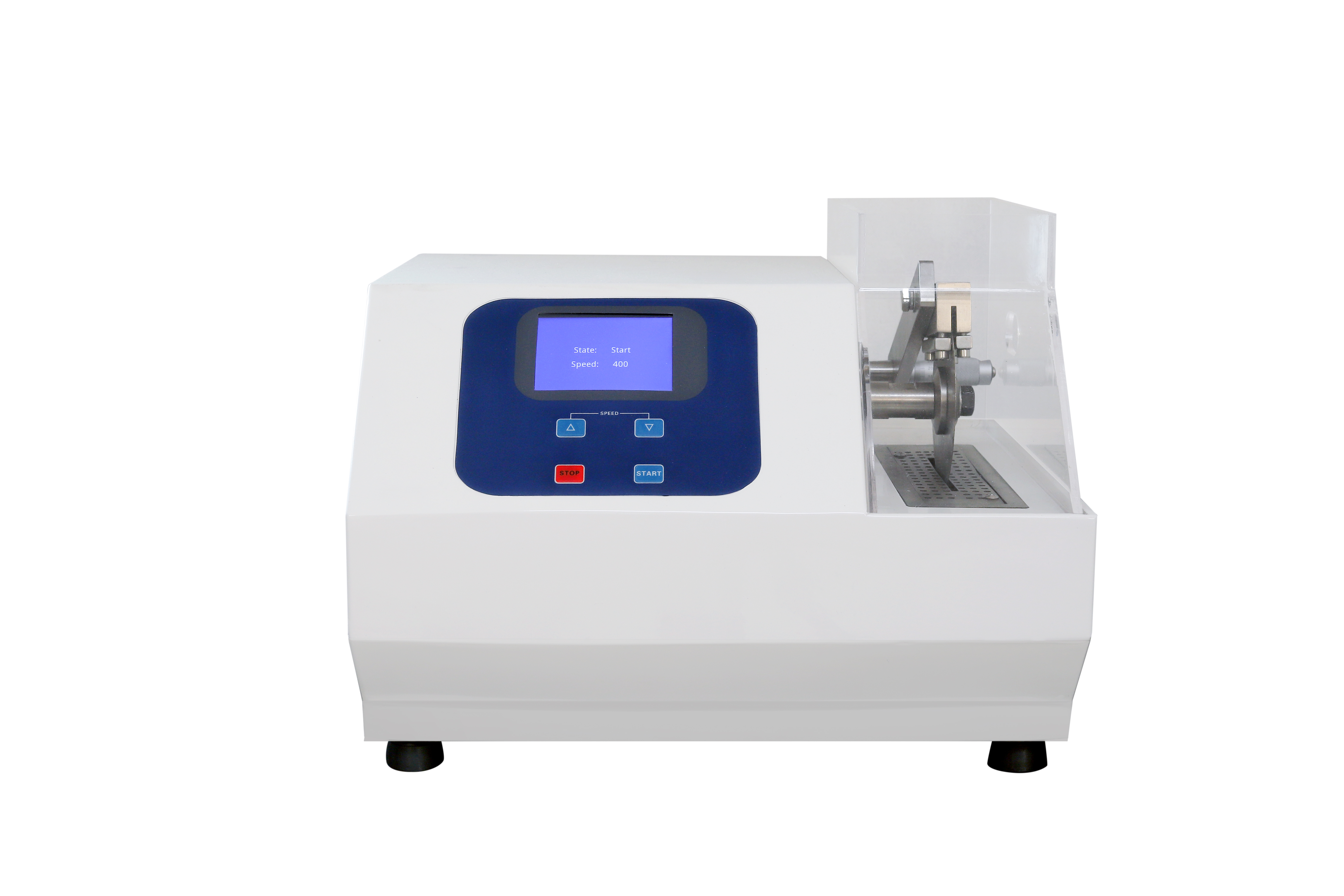

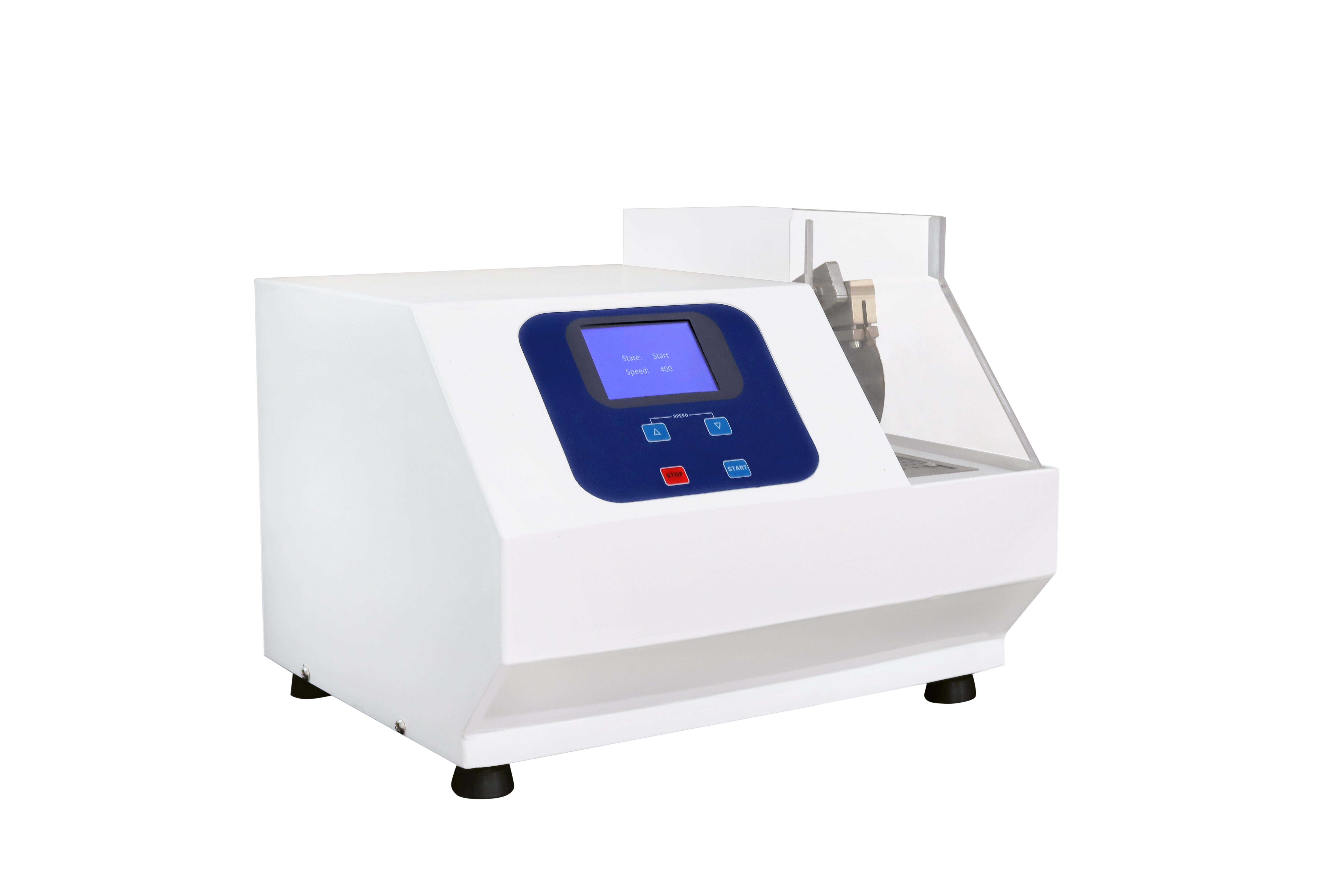

This case clearly shows the importance of choosing a suitable precision cutting machine. There are several key factors to consider when making this choice, including cutting accuracy, operational efficiency, reliability, and compliance with international standards. Let's take a closer look at each of these factors and how the DS - 600 precision cutting machine from Laizhou Jincheng Industrial Equipment Co., Ltd. meets these requirements.

Cutting accuracy is crucial in material testing. A high - precision cut ensures that the sample used for testing accurately represents the properties of the material. The DS - 600 is equipped with a high - precision spindle and four highly adaptable clamps. These features allow for precise positioning of the material, ensuring that the cutting accuracy can reach up to 0.05mm. In a comparison test, it was found that the DS - 600 could produce cuts with a variance of less than 0.03mm, while ordinary cutting machines had a variance of up to 0.2mm. This high level of accuracy is essential for industries such as aerospace and automotive, where even the slightest deviation can lead to significant performance differences.

Operational efficiency is another important factor. The DS - 600 is designed with a limit switch, which enables unmanned operation. It can complete a cutting task within an average of 15 minutes, while an ordinary cutting machine may take up to 30 minutes for the same task. This means that the DS - 600 can increase the daily production capacity of a material testing laboratory by up to 50%. This high - efficiency operation is beneficial for companies that need to conduct a large number of tests in a short period.

Reliability is the foundation of any equipment. The DS - 600 is made of high - quality materials and undergoes strict quality control during the manufacturing process. Its failure rate is as low as 1% per year, while the failure rate of ordinary cutting machines can reach up to 5%. This low failure rate reduces maintenance costs and downtime, ensuring the continuous operation of the material testing process.

In the global market, compliance with international standards is essential. The DS - 600 meets international standards such as ISO 9001. This means that the test results obtained using the DS - 600 are recognized worldwide, which is very important for companies involved in international trade and cooperation.

When comparing the DS - 600 with ordinary cutting machines, the advantages of the DS - 600 are obvious. As mentioned above, in terms of cutting accuracy, operational efficiency, reliability, and compliance with international standards, the DS - 600 outperforms ordinary cutting machines. These advantages make the DS - 600 a perfect choice for material testing.

In conclusion, choosing the right precision cutting machine is of great importance in the material testing industry. By considering factors such as cutting accuracy, operational efficiency, reliability, and compliance with international standards, you can make an informed decision. The DS - 600 from Laizhou Jincheng Industrial Equipment Co., Ltd. is the perfect solution to the material testing cutting problems. It offers high - precision cuts, high - efficiency operation, reliable performance, and compliance with international standards.

If you are looking for a precision cutting machine that can meet your material testing needs, don't miss the DS - 600. Click here to learn more about the DS - 600 and how it can revolutionize your material testing process!