Universal testing machines (UTMs) are essential tools in modern manufacturing and material science industries. They enable precise measurement of mechanical properties such as tensile strength, compression resistance, and elasticity. However, the true value of these machines lies not only in their operation but also in the accurate processing and interpretation of the data they generate.

Raw data from a universal testing machine is just the beginning. Without proper processing, this data may lack clarity and actionable insights. Effective data processing ensures that test results are reliable, repeatable, and suitable for decision-making. For instance, in the automotive or aerospace industries, even minor variations in material performance can have significant implications on product safety and longevity.

The operation of a UTM involves several critical steps:

Modern UTMs come equipped with advanced software for real-time data visualization, trend analysis, and result reporting. These features allow users to:

For example, a manufacturer of polymer composites used UTM data to optimize the formulation of a new material. By analyzing the elongation at break and tensile strength, they were able to improve the product’s durability by 20%.

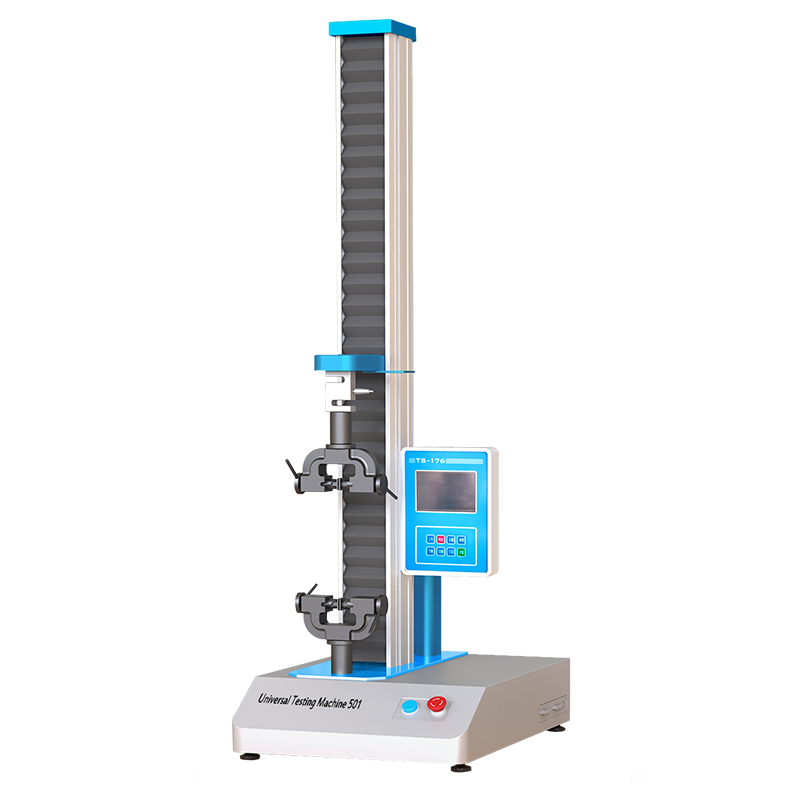

The UTM-10KN is a high-performance universal testing machine designed for a wide range of materials, including metals, plastics, and composites. It offers a maximum load capacity of 10 kN and is ideal for laboratories and production environments requiring precision and reliability.

| Feature | Specification |

|---|---|

| Maximum Load Capacity | 10 kN |

| Testing Speed Range | 0.001–500 mm/min |

| Sample Size Compatibility | Standard and custom fixtures available |

One of our clients, a leading manufacturer of medical devices, implemented the UTM-10KN into their quality control process. By using the machine's built-in data processing capabilities, they reduced testing time by 30% while improving accuracy. This allowed them to meet strict regulatory standards and enhance customer trust.

Another case involved a construction materials company that used the UTM-10KN to evaluate the performance of reinforced concrete samples. The detailed stress-strain data provided by the machine helped them refine their design and achieve a 15% increase in structural efficiency.

Whether you're a researcher, engineer, or quality control specialist, the UTM-10KN offers the precision and versatility needed to support your material testing requirements. With its user-friendly interface and powerful data analysis tools, it is an investment that delivers long-term value.

Ready to experience the benefits of accurate material testing? Discover more about the UTM-10KN today and take your testing process to the next level.