In today's fast-paced industrial and scientific environments, precision in measurement is more than a necessity—it's a competitive advantage. The 3D Moving Bridge Coordinate Measuring Machine (CMM) by Laizhou Jincheng Industrial Equipment Co., Ltd. sets a new benchmark for accuracy and reliability, designed explicitly to meet stringent international standards.

Central to the machine's outstanding performance is its integration of the Renishaw UCC control system, renowned across industries for ultra-precise positioning and smooth dynamic movements. Combining this with the high-performance calibration sphere and Rational-DMIS software, the system achieves measurement repeatability with deviations as low as ±0.002 mm, a critical factor for quality assurance in complex manufacturing processes.

Furthermore, the Rational-DMIS interface, lauded for its user-friendly design, significantly shortens operator training times — a crucial benefit for organizations aiming to minimize downtime while maximizing output quality.

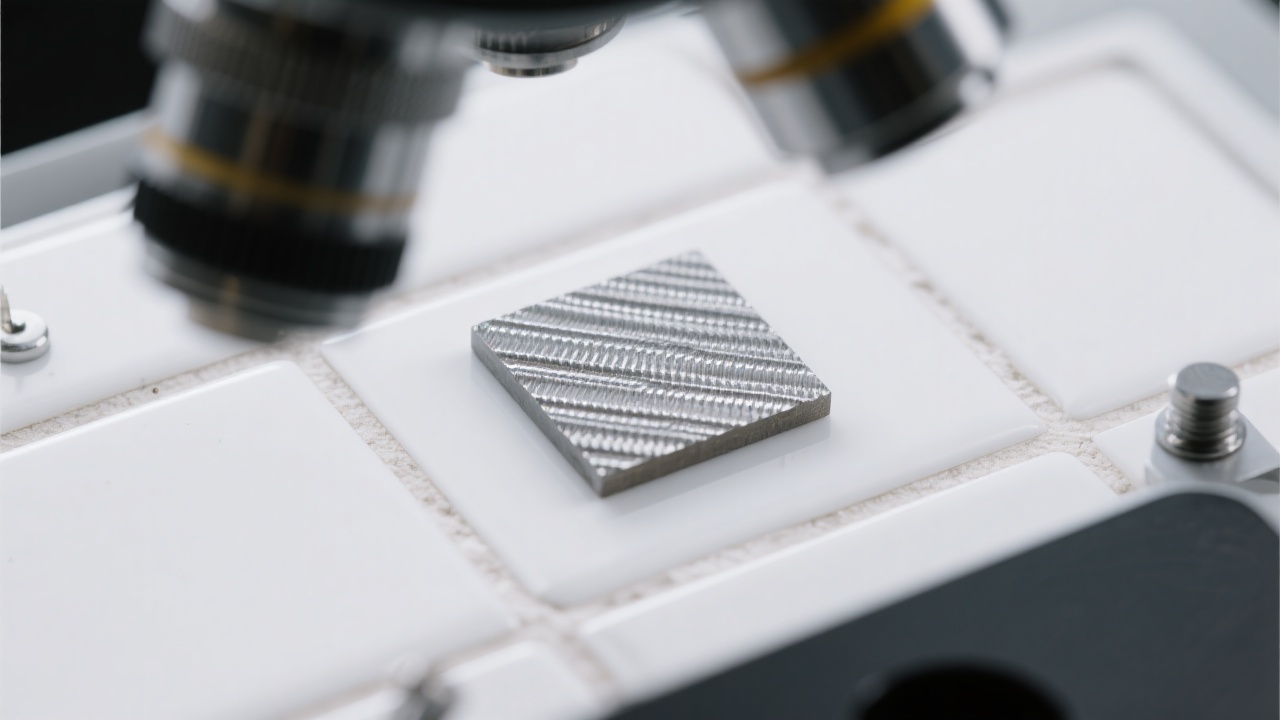

A powerful onboard computer paired with high-precision probe combinations enables the CMM to accurately measure materials ranging from sensitive alloys to hard metals, accommodating heterogeneous surfaces with ease. Such adaptability is critical in mechanical manufacturing, metallurgy testing, and cutting-edge research contexts.

By adhering to international ISO 10360 standards, the instrument offers authoritative and reliable outcomes, reassuring engineers and scientists that their data interpretations are built on trustable foundation measurements.

Consider a precision mechanical manufacturer that integrated this CMM into its quality control line. The firm reported a 25% reduction in inspection cycle time and a 40% decrease in product nonconformity rates within the first six months, directly translating to cost savings and enhanced client satisfaction.

Similarly, a university metallurgical lab employed the system to validate nano-texture surface treatments, citing that the high repeatability improved experimental reproducibility by over 30%, a critical enhancement for peer-reviewed research results.

| Application Area | Measured Parameter | Impact |

|---|---|---|

| Mechanical Manufacturing | Dimensional Accuracy (±0.002 mm) | 25% faster inspection, reduced defects |

| Metallurgy Testing | Surface Roughness & Texture | Improved research reproducibility by 30% |

| Scientific Research | Precision Spatial Coordinates | Reliable data for high-impact publications |

In complex supply chains and R&D projects, data accuracy fuels confident decision-making. The 3D Moving Bridge Coordinate Measuring Machine empowers engineers and scientists to detect even the smallest deviations early, ensuring corrective actions that save millions in potential downtime and product recalls. Its ergonomic software and hardware design further promote safer and more efficient workflows.

Prospective users in mechanical manufacturing, metallurgy, or research institutes should seize the opportunity to leverage this technology for superior quality assurance and scientific accuracy.

Interested in transforming your measurement capabilities? Discover how Laizhou Jincheng Industrial Equipment's 3D Moving Bridge Coordinate Measuring Machine can redefine accuracy and efficiency for your operations. Whether your focus is rapid inspections or advanced metrology, this solution stands ready to elevate your standards.