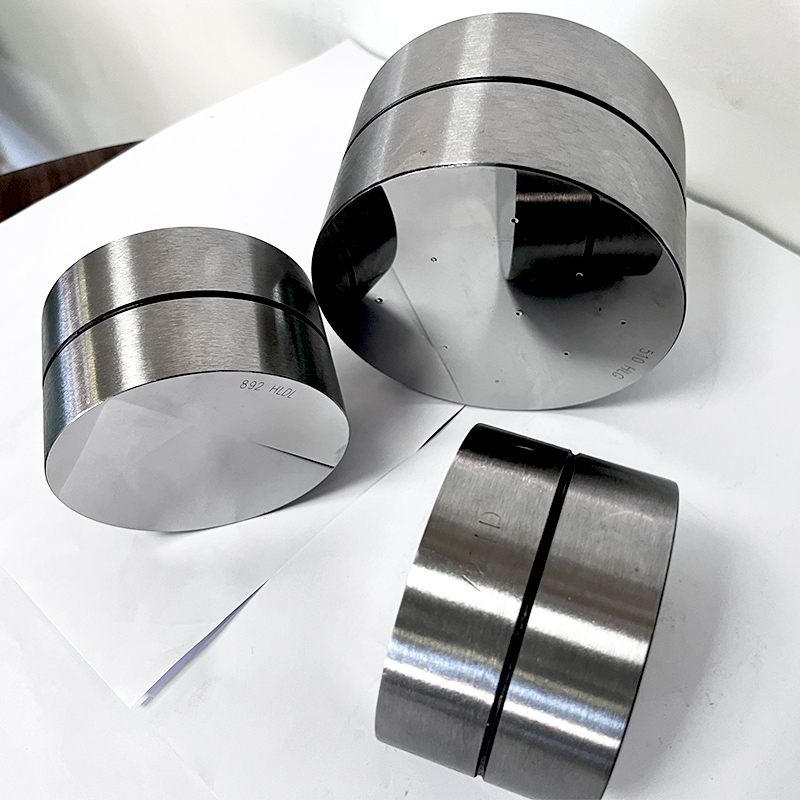

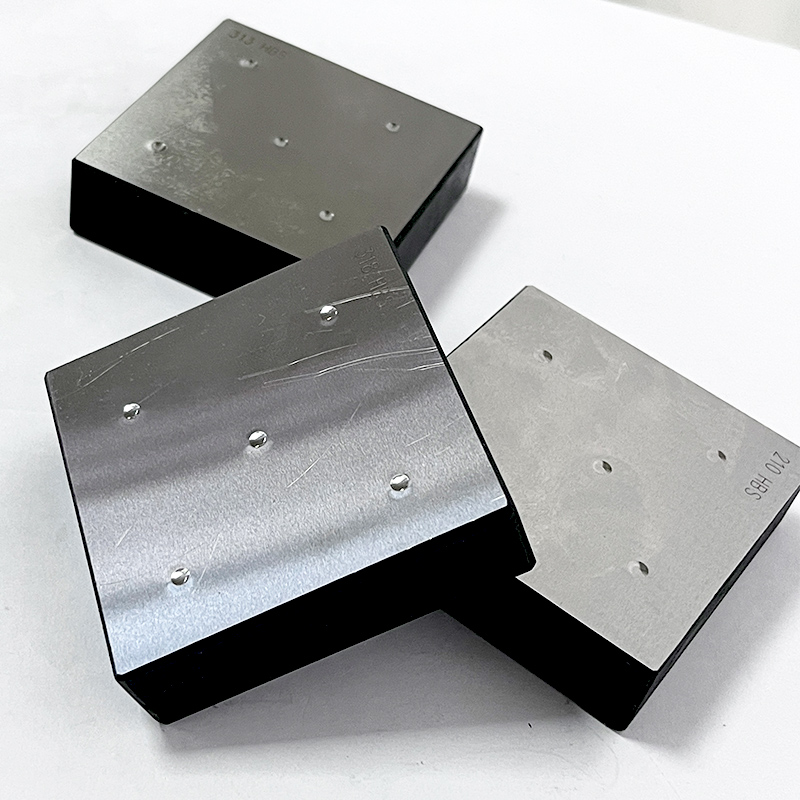

Hardness blocks are an important tool for calibration and inspection of hardness testers. They are precision machined and hardness calibrated to have known, uniform and stable hardness values. Testing hardness blocks with a hardness tester can determine the accuracy and precision of the hardness tester's measurement. Hardness blocks are widely used in machinery manufacturing, metal processing and other industries to ensure that hardness measurement equipment is working properly and reliably, and that the hardness of the workpiece meets production standards.

1. Ultra-high precision calibration: Using advanced nano-level calibration technology, the hardness value error is controlled within a very small range, ensuring that each test data is accurate and reliable, providing a solid data foundation for metallographic analysis.

2. Special materials and craftsmanship: Made of high-quality alloy materials and undergoing multiple fine heat treatment processes, the surface hardness is uniform and wear-resistant. It can still maintain stable performance during frequent use, and its service life far exceeds that of ordinary hardness blocks.

3. Integration of multiple hardness scales: Integrates multiple commonly used hardness scales such as Rockwell, Brinell, Vickers, etc. to meet the needs of different metal materials and various tests. Compatible with a variety of metallographic hardness testing equipment, flexible and convenient operation.

4. Strict quality control: Each hardness block undergoes strict quality inspection in multiple dimensions and is accompanied by authoritative certification to ensure the accuracy, consistency of the hardness value and the credibility of the test results.

1. Metal material research: In metal material research in universities and research institutes, it is used to calibrate hardness testing equipment and assist in studying the relationship between material microstructure and hardness.

2. Machinery manufacturing enterprises: Help machinery manufacturing enterprises detect the hardness of parts and components, control product quality, and ensure the stability and reliability of mechanical products during use.

3.Automobile and aerospace industry: Test the hardness of automobile engine parts and aerospace precision parts to meet the high standards of the industry and ensure the performance of key components.

4. Quality inspection agencies: As standard reference samples, they are used for quality control and equipment calibration of various metal material hardness tests to enhance the authority of the test results.

Superficial Rockwell hardness

Hammer Brinell Hardness Tester

Plastic Rockwell Hardness Tester